Today’s business world is characterized by rapid change and growing competition. Companies need to increase their efficiency and optimize their processes to stay in the race. In this blog post, we will focus on the importance of the Watchmen platform for optimizing production processes and explore the numerous benefits it offers. But before we take a closer look at the platform, we will take a look at the importance of AI and IoT in the industrial context.

AI and Industrial IOT Technologies

The ongoing digitization and use of technologies such as Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT) have changed the way companies optimize and operate production processes. The combination of these two technologies has the potential to revolutionize companies and give them a decisive competitive edge.

The diagram shows the most important areas of application for artificial intelligence (AI) in industry. The three most common use cases are predictive maintenance, quality control and process optimization.

Predictive maintenance uses data and analytics to plan maintenance actions on machines and equipment. AI models can accurately determine maintenance needs and intervals to achieve higher machine availability and reduce downtime. Pattern recognition algorithms can identify and reject defective products on the shop floor, improving quality control. AI can also be used to make production processes more efficient and effective, for example by reducing energy consumption or eliminating bottlenecks. The Watchmen platform offers precisely these three functions.

In addition, a study shows that 83% of companies that have implemented IoT technology have increased their efficiency as a result. The Watchmen platform is based on an IoT architecture and uses advanced AI models to detect potential failures and provide optimization recommendations. Companies that want to optimize their production processes and remain competitive should consider the Watchmen platform.

The Watchmen Platform

Using the Watchmen platform has the potential to take companies’ production processes to a whole new level. With the industrial IOT platform, companies can increase their efficiency and optimize their production processes. The benefits of the platform are numerous and include:

- Real-time detection of potential failures

- Automatic optimization recommendations

- Easy to understand visualization of data

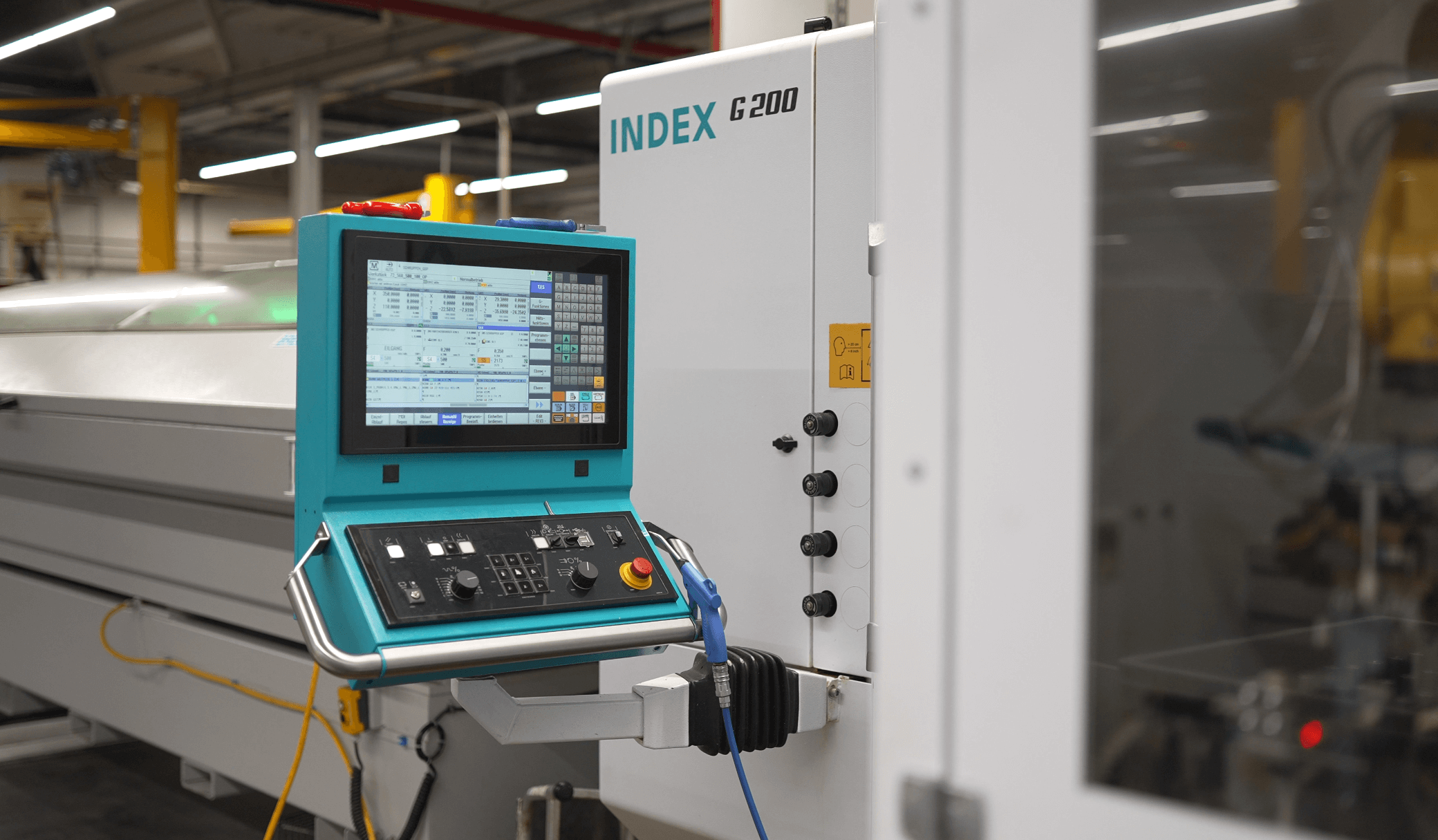

- Seamless integration with all production machines

- Efficiency increase of up to 30 %

- AI implementation

The platform uses artificial intelligence based on the AVA sensor to enable real-time monitoring of production processes. The sensor processes vibrations and detects the state of the machines – whether they are in production, preparation or idle. The application of cycle counting and anomaly detection enables continuous monitoring of machine states and detection of deviations from the norm.

Watchmen functionalities

The Watchmen platform provides comprehensive monitoring and optimization of production processes and visualizes the data in an easy-to-understand way.

An example of a Watchmen platform visualization.

The Watchmen platform dashboard gives the user a complete overview of the status of all machines in real time. It is easy to use and shows all important information at a glance: from machine names and runtime to shifts and state.

For companies, the calculation of OEE (Overall Equipment Effectiveness) is of great importance as it measures the effectiveness of the machine based on availability, productivity and quality. With this feature, companies can measure and optimize their machines more effectively to further improve their production processes.

The platform is also equipped with an intelligent alert function that sends notifications when the status of a machine changes. This allows users to proactively respond to potential problems and minimize downtime. But that’s not all! The platform also provides detailed insights into the effectiveness of machines and their production processes. Users can analyze historical data and make predictions to optimize processes.

Data Security

Data security is a top priority for businesses and customers. The Watchmen platform enables seamless monitoring of machine conditions using AI-based data processing on AVA. The results are then stored in small data stores for the next month, containing only the necessary data for the customer. In this way, the customer can review the results and make adjustments as necessary to further optimize production processes.

To enable fast and easy-to-understand visualization of the data, all data is provided on the Watchmen platform. However, only the necessary data points are stored to ensure high data security and protection of customer data. Watchmen thus offers a perfect balance between data security and transparency to provide customers with optimal service.

Fazit

AI and industrial IoT technologies have the potential to take enterprise manufacturing to a new level. Integrating these technologies into the Watchmen platform enables companies to increase efficiency and optimize their production processes.

To learn more about the Watchmen platform, contact us.