AI-controlled Machine data acquisition! Machine data monitoring! Full Factory monitoring! But how does it work?

How many production machines are digitized in Germany?

60%

of the production machines

According to a study conducted by the VDMA in 2023, around 60% of production and manufacturing machines in Germany are digitalized. This corresponds to around 2.4 million machines. The study shows that the digitization of production in Germany has progressed significantly in recent years. In 2020, around 40% of machines were still digitized. ¹

More than +0 Machines in only 3 years

In an era where machine data is the lifeline of the modern manufacturing industry, the ability to efficiently and accurately capture this data has a profound impact on the performance and competitiveness of manufacturing companies.

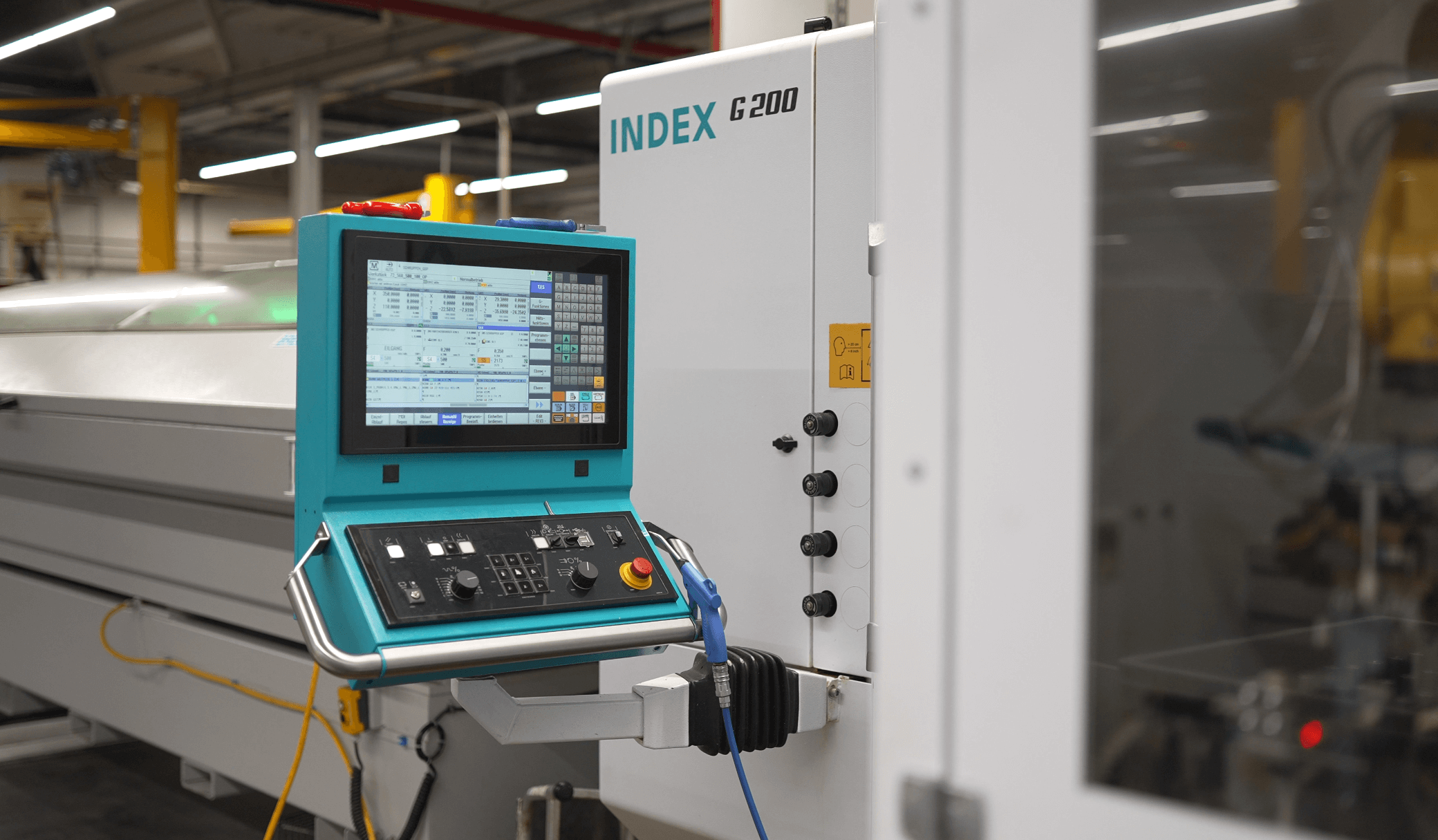

Revitalize and Retrofit: A Crucial Leap Towards Effective Machine Data Acquisition

Navigating through the challenges in traditional machine monitoring, the importance of retrofitting older machines with IoT sensors becomes paramount to harness the full potential of machine data acquisition and collection. The inadequacies and consequential financial implications of outdated systems, especially amidst escalating energy and labor costs, are notably significant. Retrofitting not only revamps these machines but also introduces an era where accurate and timely machine data collection is a reality, mitigating the risks of error-laden processes that amplify production costs and undermine product quality. Therefore, by strategically embedding IoT sensors, businesses not only ensure high-quality machine data acquisition but also pave the way for robust machine data analytics, carving a path towards operational optimization and astute, data-driven decision-making in the manufacturing realm.

Machine data acquisition is the backbone of digital production

Machine data acquisition has established itself as the backbone of digital production by acting as the foundation for insightful, data-based decision-making and optimization of operations.

The three most common methods of machine data collection

OPC UA has established itself as one of the key elements in Industrie 4.0 by providing a secure and reliable mechanism for information exchange across the different levels of the automation pyramid.

PLCs have played a central role in industrial automation and machine monitoring for decades. These robust, reliable devices not only control machines, but also collect a wealth of data from the production environment.

Edge computing in machine data acquisition has gained significant importance in recent years, especially in contexts where real-time data processing is essential. The method enables local data processing directly at the machine, which not only reduces latencies but also minimizes the load on network resources.

Edge computing: Ideal for small to medium-sized enterprises (SMEs)

Company size: 1 – 500 employees

Reason: Edge computing, the most advanced method among those mentioned, offers SMEs the advantage of processing data close to the point of origin, which both reduces latency and frees up network resources. Especially for companies that may not have the resources for extensive centralized data processing systems, edge computing enables effective data analysis and use without large infrastructure investments. SMBs can benefit from the scalability and adaptability that edge computing enables, making the most of their technology investments.

OPC UA: Ideal for companies with modern, big machine parks

Company size: 500+ employees

Reason: OPC UA, known for the bridge it bridges between legacy and modern methods, offers interoperability and data security benefits to large enterprises, especially those with extensive or modern machinery. For large-scale production facilities where different machines and systems need to communicate with each other, OPC UA enables secure and efficient data transmission across different levels and locations. Large enterprises with the resources for implementation and maintenance can benefit from a consistent, enterprise-wide data platform enabled by OPC UA.

PLC: Ideal for traditional manufacturing companies and specialized applications

Company size: Variable (from SME to large enterprise).

Reason: PLC systems, considered the oldest method among those mentioned, are not necessarily limited to a specific company size, as they can be used in a wide variety of applications and environments. They are particularly useful for companies that rely on traditional manufacturing processes or have specialized applications where robustness and reliability are paramount. PLCs have been established for decades and provide a reliable solution for machine control and the simplest form of machine data acquisition.

In summary, while each technology brings its own strengths and weaknesses, it is the steady progress in machine data collection and intelligent machine monitoring that will shape the future. It remains critical that companies of all sizes continually evaluate and adapt their technology strategies to remain competitive in an increasingly digitized and connected industrial landscape.

OPC UA is very strong in terms of interoperability and provides solid data security, but can be challenging in terms of implementation costs and maintenance/management.

PLC systems are relatively efficient in terms of implementation cost and maintenance, but can be limited in terms of data processing capability and adaptability.

Edge computing scores high in adaptability and data processing capability, and while it is quite efficient in terms of implementation cost and management, these aspects can vary by application and scale.

Machine data acquisition is an important building block for the digitalization of production. By analyzing machine data, production companies can increase efficiency, productivity, cost reduction and quality. Experience data with Novo AI sensors and platform.

Conclusion: The essence of machine monitoring in advanced production

Machine data collection is not merely an advancement in technology, but has established itself as an indispensable tool in contemporary production and manufacturing industries. Whether through edge computing, OPC UA, or PLC, the true value is hidden in the data that is captured and made available through these technologies. Data empowers companies to gain deep insights into their operations, maximize process efficiency, minimize downtime, and ultimately develop cost-effective solutions.

In an era where markets are characterized by dynamic change and increasing competition, access to and use of machine data can be critical to a company’s survival in the marketplace. At a time when energy and raw material costs and global supply chains are constantly fluctuating, machine data collection provides strategic control and insight into internal operations.

In an increasingly connected and data-centric world, the ability to efficiently capture, analyze and act on machine data is no longer an option, but an essential strategy. Intelligent machine monitoring and a data-driven production environment are not only factors of optimization, but also of future-proofing and sustainability in the modern industrial era.