Monitor. Optimize. Maximize.

Every function of the platform has been carefully developed for machine evolution.

Regardless of the machine manufacturer, machine type or year of manufacture.

Milling machines. Lathes. Grinding machines. Injection molding machines. Assembly lines. Textile machinery. We connect your machinery.

Set your machinery to high performance! With Novo AI's technology, you can immediately see which machines deliver top performance and where optimization is required.

Every second of inefficient machine operation costs money. Novo AI enables you to identify performance deviations in real time and take immediate action. Avoid costly downtimes before they occur.

Novo AI provides you with the tools to synchronize your machines optimally. Imagine a machine park that is as precisely coordinated as an orchestra - for maximum efficiency and productivity.

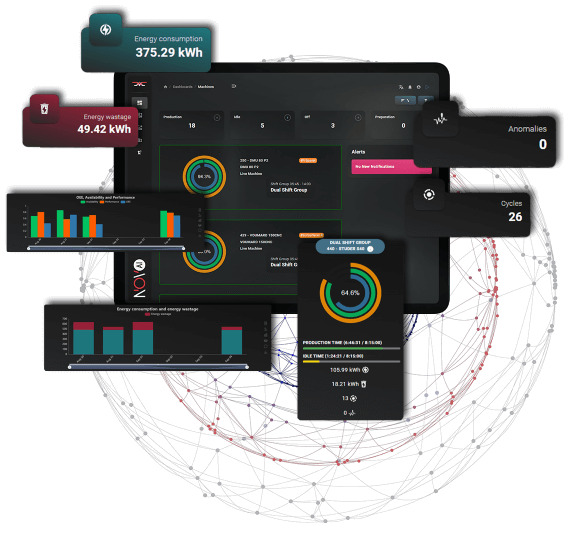

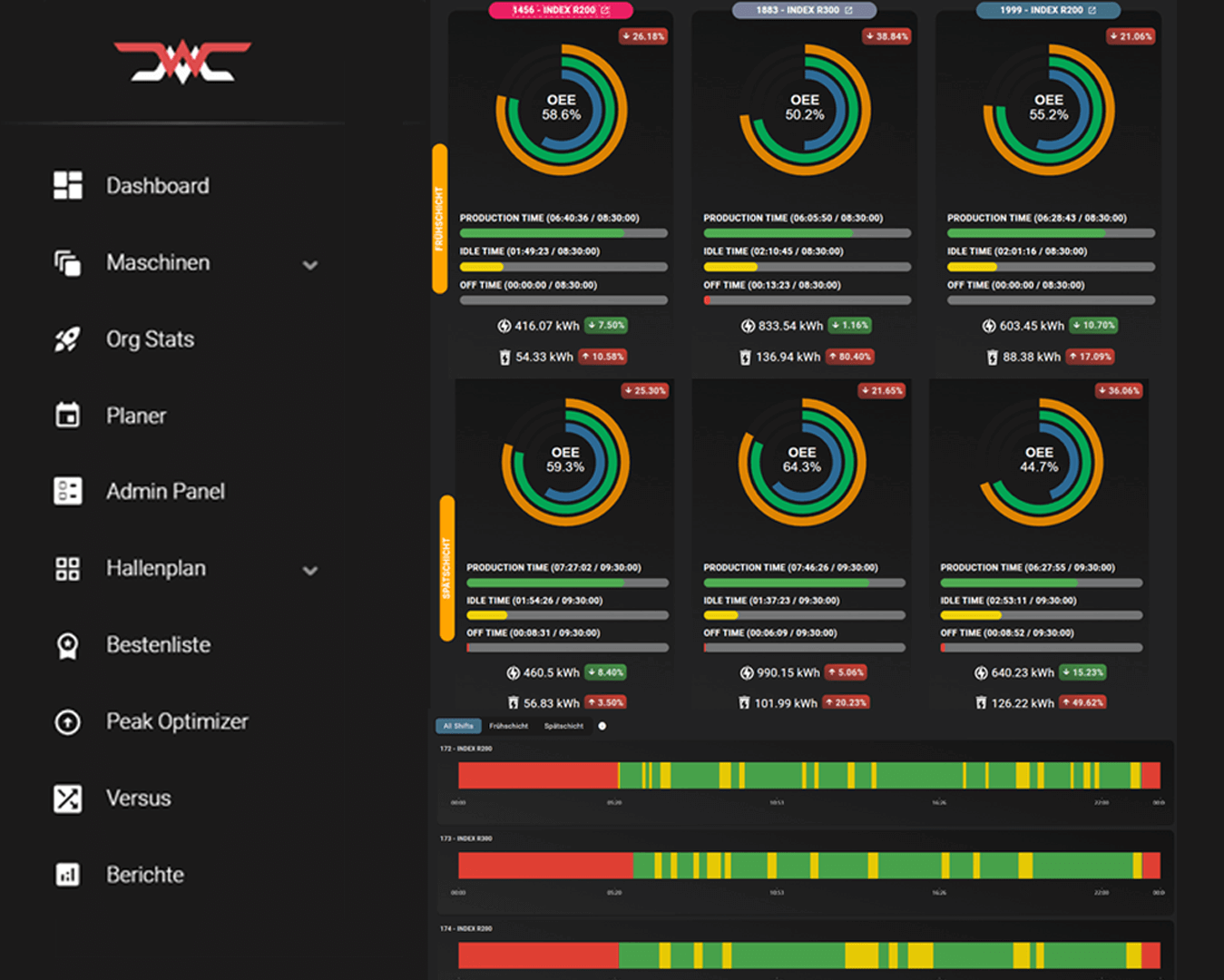

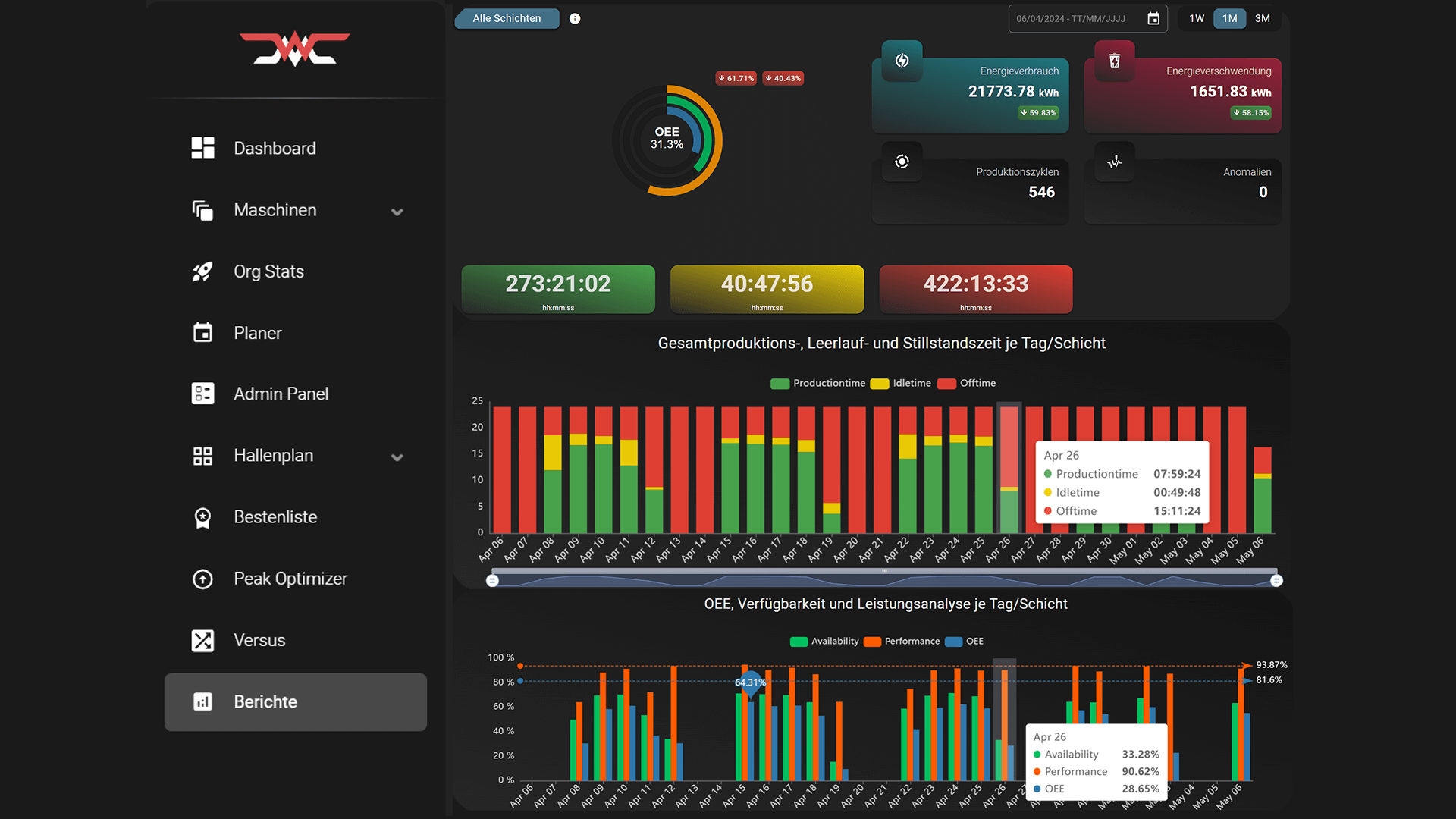

Imagine if you could monitor every aspect of your production line in real time - OEE, performance, availability - and immediately know where to start to make your efficiency shoot through the roof. Our reports cover just that!

Energy is money. Money that you should not spend unnecessarily. Our reports show you where you are wasting energy and how you can turn this waste into savings. Optimize your energy use, reduce your costs and improve your environmental footprint at the same time.

Minimize downtime decisively by identifying exactly which machines are slowing down your production. Our precise reports reveal where and why breakdowns occur and enable you to take targeted action.

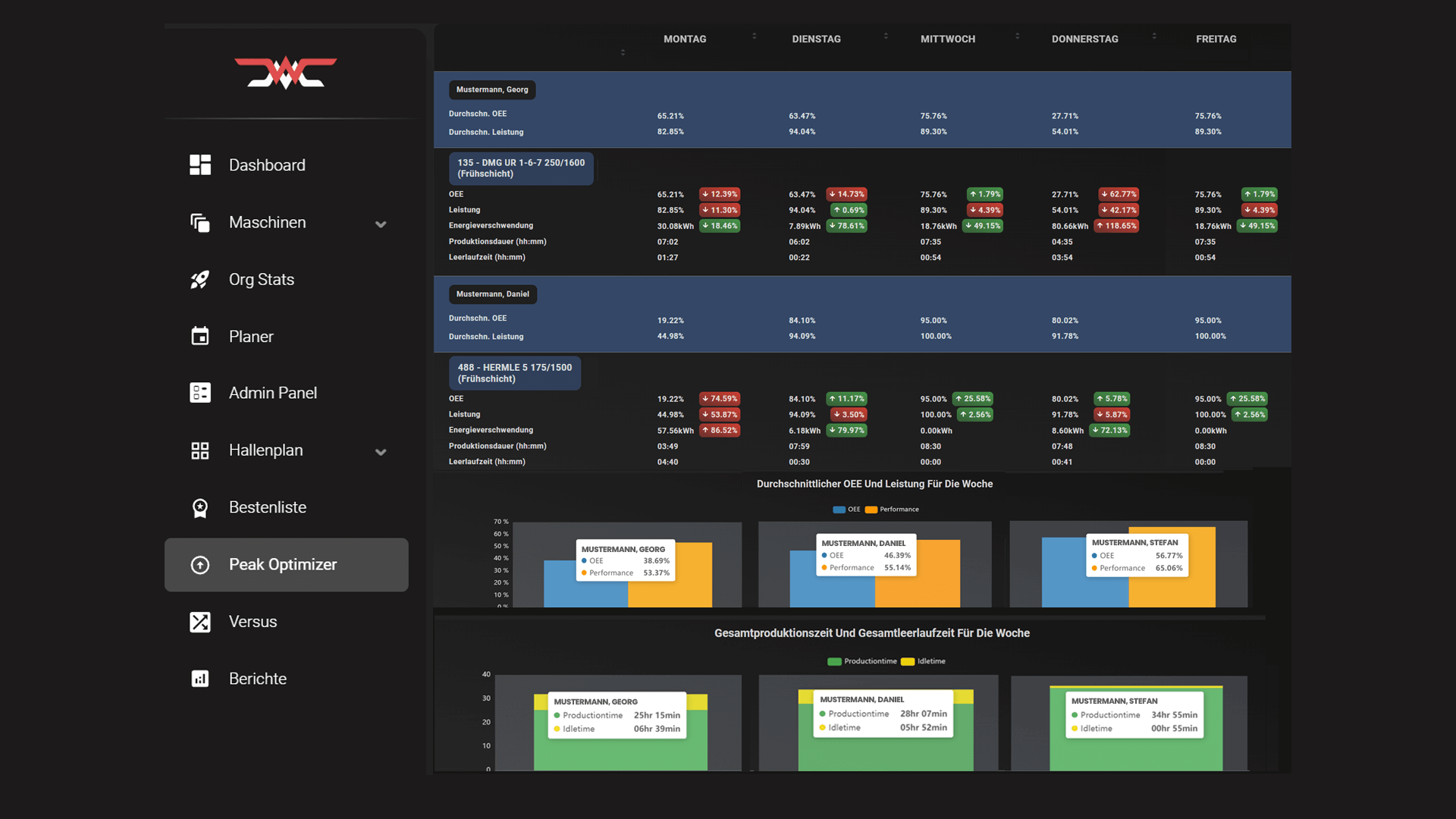

With our "Peak Optimizer" feature, we create a transparent presentation of performance data, which creates a culture of recognition and reward for above-average performance.

Your employees are the heart of your production. When you measure their performance in real time, you set a new standard for efficiency and engagement. With our tools, you can immediately identify where bottlenecks occur, who needs support and how you can maximize the efficiency of each individual.

Think bigger, faster, better - with data that helps you not only make personnel decisions, but perfect them. Unlock the full potential of your team, minimize errors and drive your production like you never thought possible.

And that's not all. Features like Shift planner Anomaly detection Best lists Hall plan Machine park comparison Plant planner Co2 balance report Energy optimizer Reasons for downtime are waiting for you!

You can view your reports and machine data via our user-friendly IoT platform "Watchmen", which provides you with real-time access and analysis.

All industrial production machines can be retrofitted with our sensor, regardless of manufacturer, type, year of manufacture or existing technology.

Our advanced sensor measures vibration, acoustics, temperature, humidity, current and processes this data directly on site on the sensor - without a cloud connection. This data is intelligently correlated with the machine status using AI algorithms to display critical performance indicators in real time. In this way, Novo AI enables precise monitoring and optimization of your production processes, non-invasively and regardless of machine type or age.

The Watchmen platform is your secret weapon in an industry dominated by efficiency pressures and cost savings. It provides real-time monitoring and analysis of your machines so you can predict breakdowns and optimize maintenance times, resulting in massive cost savings. With this powerful tool in your arsenal, production delays and costly downtime will be a thing of the past.

Find your personal solution.

Unleash your potential. Get in touch with us today!

Free of charge

Pioneer Plan

Subscribe

Advanced analytics

Subscribe

AI peak performance

OEE (overall equipment effectiveness)

Get real-time data on machine efficiency on the WatchMen platform

Basic machine analysis

Availability monitoring, performance analysis and runtime visualization of machine data in real time

Advanced machine analyses

Energy consumption, energy waste and analysis of historical machine data

Machine analysis at SMART Factory level

Product counters, automated reports, machine comparisons and insights through AI optimization

Do you have a question or would you like more information? We are here for you!