With the rise of technology, Big Data has revolutionized the production industry standards to a remarkable extent. The rapid increase in the use of devices and other ways of communication has contributed to the collection of massive amounts of data.

1. High precision: Before the introduction of big data, investing in good equipment was good. However, today, with the aid of Big data, manufacturers can optimize the production processes and avoid errors.

2. Better predictions: Supply chain and demand forecasting are two key tools. They can determine the production volume, and control the production schedule, inventory, and shipments in the warehouse. You can understand the change of process in the supply chain relationship and can therefore choose good production conditions to start.

3. Track performance: If a supplier provides inferior products, you can calculate possibilities and determine the right route of action. Also, you can weigh the cost of choosing a new partner or remaining with the existing one.

4. High traceability: Big data makes the production processes transparent and traceable. It can report, how much raw materials were lost during the production process and the phase and output of a given batch. it can help the manufacturer track production stages. As a result, provide insight and analysis into areas that may be inefficient.

5. High customization: Big data recommends reasonable use of raw materials by obtaining information to create advanced customization work. You can also use reverse engineering to provide new solutions.

6. Return and operational efficiency: Big data enables producers to gain insights into the efficiency of operations e.g. new equipment or advertising strategies.

Regardless of big or small data, the application of data in the production industry is currently feasible and trending in two directions:

1. To create the optimization of IIoT production lines and supply chains.

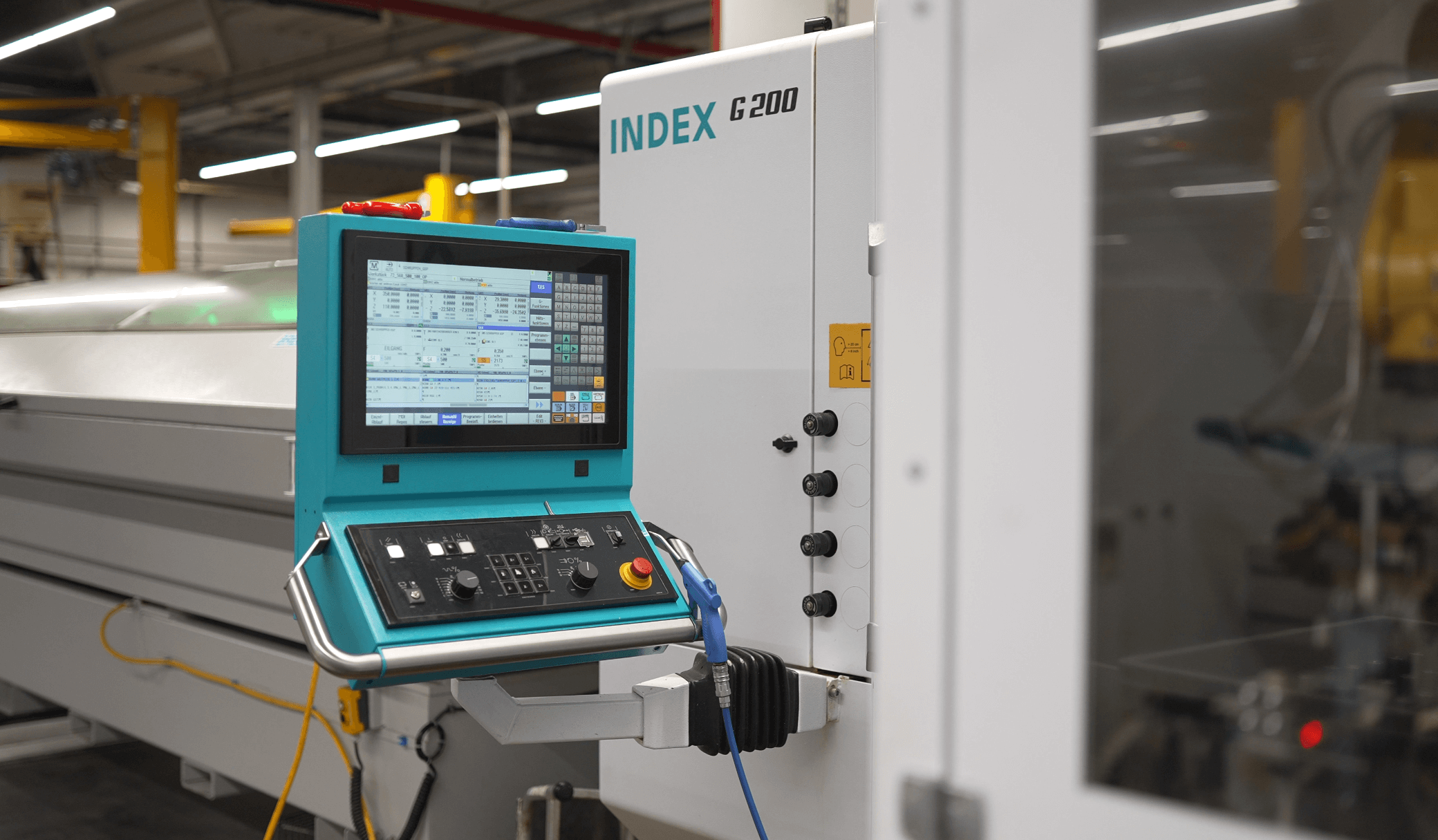

2. To create the optimization of IIoT, the company installs sensors on machines to detect various information like temperature, pressure, heat, vibration, noise, etc. Which is used to perform equipment diagnosis, power consumption analysis, energy consumption analysis, quality accident analysis, etc. Some companies use completely unmanned automation. E.g. In Production, once standard processes are deviated from, it alerts the right department, and the error is rectified.

The direction of supply chain optimization is mainly to obtain various types of data in warehousing, distribution, and sales, and even aggregate customer information, internal enterprise information, and supplier information into the supply chain system, and optimize through data collection and analysis on the supply chain. Supply chain, to achieve rapid response to customers and reduce costs.

For more information on how to use Big Data in your company, contact us.