Improve Production With AI: How Artificial Intelligence Increases Reliability and Prevents Failures in Manufacturing

Production reliability is one of the most critical factors in industrial environments. When machines fail or processes break down due to technical errors, corrosion, or component fatigue, the consequences can be severe. Unexpected downtime increases operational costs, delays delivery times, and may cause safety risks or damage to equipment. According to the German Federal Environment Agency, corrosion was among the most frequent causes of production malfunctions in 2019, highlighting just how vulnerable industrial processes can be.

As manufacturing becomes more complex and competitive, companies are looking for advanced solutions to improve production with AI and make their machinery more resilient. Artificial intelligence offers new ways to detect weaknesses, predict failures, and optimize systems before disruptions occur. This article explores how AI enhances production reliability, compares traditional and AI-based analysis methods, and explains why adopting AI is essential for companies preparing for Industry 4.0.

Why Poor Reliability Evaluation Leads to Production Losses

Every machine has a lifecycle. As equipment ages, the probability of defects increases. When reliability is poorly evaluated, small issues go unnoticed and eventually escalate into serious failures. This results in:

-

Unexpected production stops

-

Reduced output

-

Damage to equipment

-

Increased safety risks

-

Higher repair costs

-

Lower competitiveness

Many companies rely on manual inspection or fixed maintenance schedules, which are often too infrequent or too conservative. If inspections occur too late, failures happen before interventions are planned. If inspections occur too early, companies waste time and resources servicing machines that are still in good condition.

In both scenarios, production becomes less efficient and less predictable. Poor reliability evaluation means operating with limited insight, making it difficult to plan and optimize processes. Modern manufacturing requires a faster, more precise, and more scalable approach to improve production with AI.

Traditional Reliability Analysis Methods: Useful but Limited

Before the rise of Industry 4.0, reliability analysis relied heavily on statistical models, manual inspections, and engineer expertise. Traditional methods include:

-

Failure Mode and Effects Analysis (FMEA)

-

Fault Tree Analysis (FTA)

-

Reliability block diagrams

-

Weibull distribution modeling

-

Condition logs and manual performance reports

While these tools offer valuable insights, they suffer from several limitations:

-

They depend heavily on human interpretation, which can be subjective or inconsistent.

-

They often react to failures instead of predicting them, making them less effective in dynamic production environments.

-

They cannot process large volumes of data, which modern sensor networks generate continuously.

-

They lack real-time capabilities, meaning issues may develop unnoticed between inspection intervals.

In 2020, the Institute of Electrical and Electronics Engineers (IEEE) compared traditional and AI-based reliability methods. The study highlighted that AI techniques consistently produced more accurate predictions and responded to system changes faster. Traditional models could not match the adaptability and precision of AI-powered systems.

These findings underscore the growing need for companies to improve production with AI rather than relying solely on outdated or manual reliability modeling.

How AI Improves Reliability and Reduces Failures

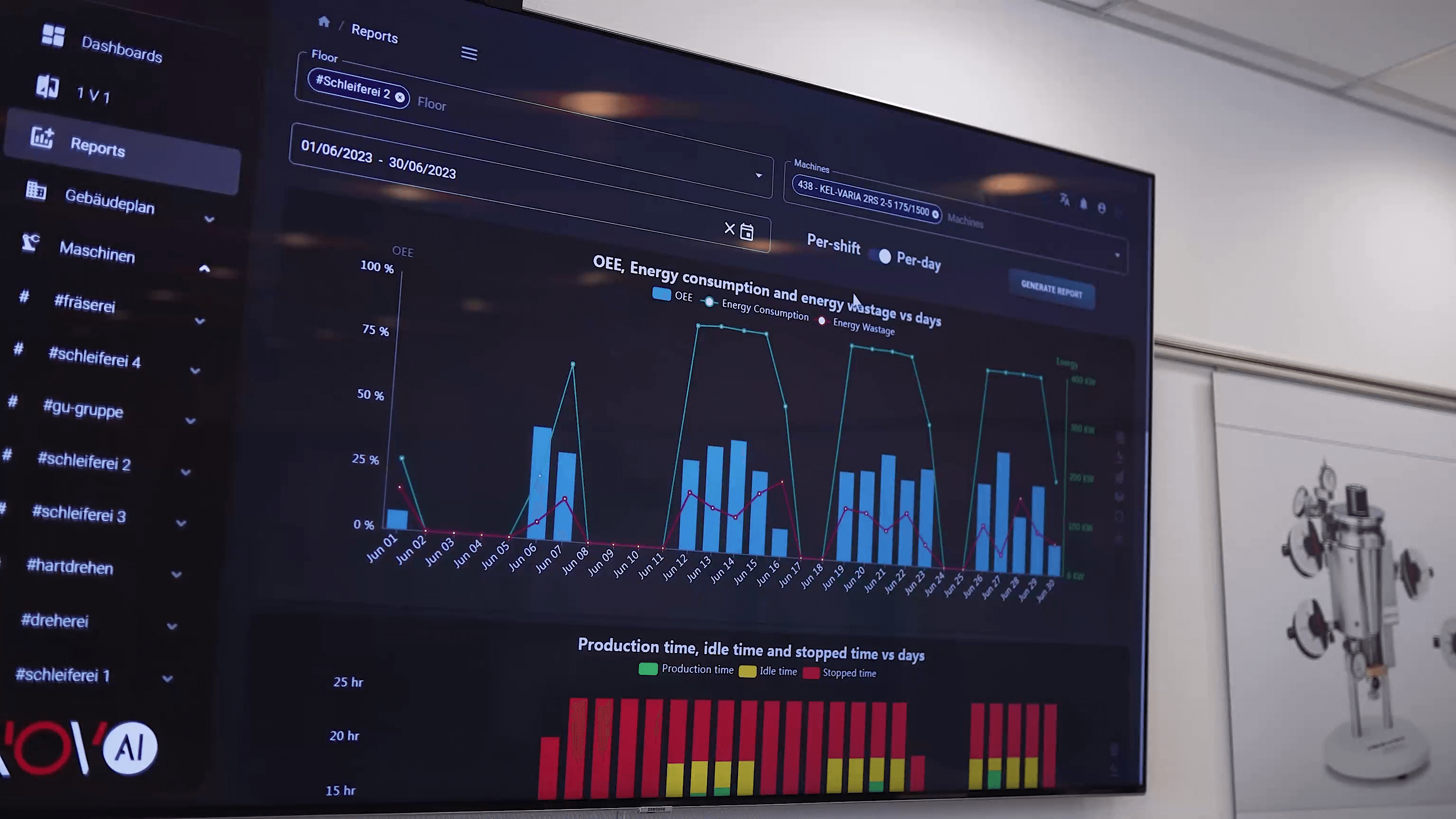

Artificial intelligence transforms how reliability is monitored, analyzed, and optimized. Instead of relying on fixed intervals or human interpretation, AI continuously learns from real production data and delivers insights in real time.

1. Superior Data Interpretation

AI systems can process vast amounts of sensor data far beyond human capability. Vibration patterns, temperature curves, pressure changes, acoustic signatures, and energy consumption all provide clues about machine health.

AI models identify:

-

early-stage anomalies

-

performance deviations

-

signs of wear and corrosion

-

abnormal behavior patterns

-

correlations invisible to traditional methods

This level of precision drastically improve production with AI and a company’s ability to detect failures before they occur.

2. Faster Decision-Making

One of the biggest advantages of using AI to improve production is the speed of analysis. AI-powered systems can evaluate thousands of data points per second, reacting instantly to fluctuations in machine behavior.

By contrast, manual evaluations may take hours or days—and often happen after the failure has already developed.

3. Predictive Maintenance Capabilities

Predictive maintenance is one of the most impactful applications of AI in manufacturing. Instead of servicing machines based on fixed schedules, companies maintain equipment only when data indicates it is necessary.

Benefits include:

-

fewer unplanned breakdowns

-

reduced downtime

-

optimized spare parts usage

-

extended machine lifetime

-

lower maintenance costs

Predictive maintenance helps companies create a more stable and reliable production environment by ensuring that interventions occur at the exact right moment.

4. Increased Safety and Reduced Risk

Failures caused by corrosion, overheating, or stress fractures can lead to serious safety risks. AI detects early warning signs long before human inspectors or traditional models would notice them.

As a result, companies can intervene earlier and prevent incidents that may lead to injuries or costly damage.

AI as a Competitive Advantage in Production

The adoption of AI is not only a technical upgrade—it is a strategic shift that enables companies to stay competitive in challenging global markets. AI helps manufacturers:

-

reduce operational costs

-

stabilize production output

-

maintain consistent product quality

-

avoid production delays

-

comply with industry standards

-

optimize energy usage

-

improve scheduling and resource planning

Organizations such as the Fraunhofer Institute for Manufacturing Engineering and Automation conduct extensive research on how AI transforms production processes and enhances reliability:

https://www.ipa.fraunhofer.de/en.html

The competitive advantage of AI is especially clear in industries with high uptime requirements, complex machinery, or large production volumes. Companies that improve production with AI now build a foundation for long-term operational excellence.

Technological Innovation for Reliability Analysis

The adoption of AI is not only a technical upgrad

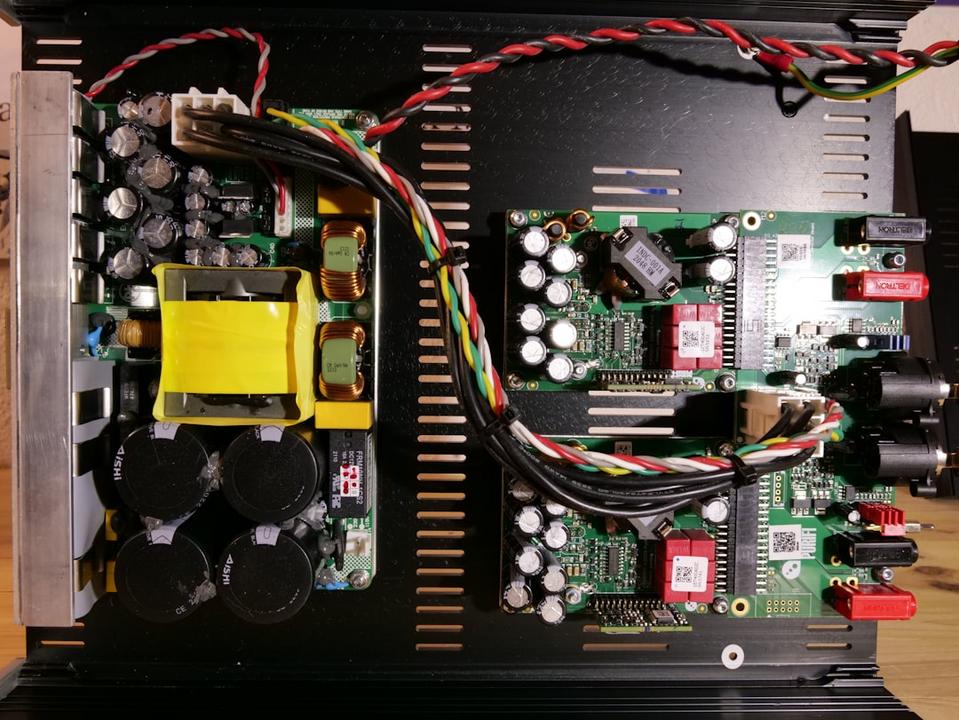

Advancements in industrial AI continue to push the boundaries of what reliability analysis can achieve. These innovations include:

-

IoT sensor networks

-

Machine learning algorithms

-

Deep learning for anomaly detection

-

Cloud-based monitoring platforms

-

Edge computing for real-time processing

-

Digital twins of production systems

These technologies allow companies to improve production with AI in ways that were impossible a decade ago. Intelligent systems no longer just report failures—they predict them, explain their causes, and guide teams toward the most efficient interventions.

Research from the MIT Sloan School of Management highlights how AI-driven operations significantly increase productivity and resilience across industries.

This progress will continue to accelerate as sensors become more precise, computing power grows to improve production with AI, and AI models become more advanced. It is a strategic shift that enables companies to stay competitive in challenging global markets. AI helps manufacturers:

-

reduce operational costs

-

stabilize production output

-

maintain consistent product quality

-

avoid production delays

-

comply with industry standards

-

optimize energy usage

-

improve scheduling and resource planning

Organizations such as the Fraunhofer Institute for Manufacturing Engineering and Automation conduct extensive research on how AI transforms production processes and enhances reliability.

The competitive advantage of AI is especially clear in industries with high uptime requirements, complex machinery, or large production volumes. Companies that adopt AI now build a foundation for long-term operational excellence.

Why Companies Should Improve Production With AI

The evolution of manufacturing is unavoidable. As monitoring technologies become more accurate, companies that cling to traditional approaches risk falling behind. Embracing AI allows organizations to:

-

reduce uncertainty

-

improve forecasting accuracy

-

increase transparency

-

strengthen their operational stability

-

transition smoothly into Industry 4.0

AI enhances reliability not through guesswork, but through measurable, data-driven insights. This shift empowers teams to operate proactively instead of reactively.

Conclusion: Improve Production With AI to Build a Reliable Future

Technical failures are not just operational inconveniences—they are costly barriers to productivity, safety, and competitiveness. Corrosion, aging equipment, and undetected wear continue to threaten production across industries. To overcome these challenges, manufacturers must adopt technologies that offer accuracy, speed, and predictive insight.

By choosing to improve production with AI, companies move beyond outdated methods and embrace a future where reliability is measurable, predictable, and continuously optimized. With AI-driven monitoring, predictive maintenance, and real-time analysis, industrial environments become safer, more efficient, and more resilient—supporting long-term success in an increasingly demanding global market.