Industry 4.0: How the Fourth Industrial Revolution Transforms Companies, Technology, and Decision-Making

The term industry 4.0 describes one of the most significant transformations in modern industrial history. It represents the shift from traditional production systems to fully connected, data-driven, and intelligent manufacturing environments. While the idea may sound futuristic, industry 4.0 is already reshaping how companies design products, optimise workflows, manage resources, and make strategic decisions.

One expert who has closely followed this evolution is Nicola Accialini, an aerospace engineer with extensive experience in product development and industrial engineering. In 2019, he founded Accialini Training & Consulting, a firm focused on supporting organisations through innovation, technology adoption, and digital transformation. His interest in industry 4.0 began in 2016, and since then he has helped companies understand both the technological and organisational implications of the fourth industrial revolution.

This article expands on insights from an interview with Nicola Accialini and examines what industry 4.0 means for businesses, how it differs from earlier industrial revolutions, what benefits it offers, and how companies can successfully implement it.

What Is Industry 4.0?

Industry 4.0 is defined as the integration of digital technologies—such as artificial intelligence, automation, sensors, robotics, cloud computing, and cyber-physical systems—into manufacturing processes. These technologies connect machines, people, and data into one intelligent ecosystem.

Accialini describes industry 4.0 as “a collection of technologies used by companies to improve productivity, reduce costs, and meet new technological demands.” Digitalisation is not an abstract concept; it is a practical set of tools designed to enhance decision-making and operational efficiency.

International institutions such as the European Commission emphasise how industry 4.0 drives competitiveness through connectivity, data usage, and automation.

The foundation of industry 4.0 is awareness—understanding what these technologies can do and how they can be applied in real environments.

How Industry 4.0 Differs from Previous Industrial Revolutions

To understand industry 4.0, it is essential to look at the earlier industrial revolutions:

1. First Industrial Revolution (1760–1850)

Mechanisation, steam power, and the rise of factories revolutionised production. Britain led this transformation.

2. Second Industrial Revolution (1870–1914)

Electricity, mass production, and early automation accelerated global industrial development in Germany, the United States, Japan, and several European nations.

3. Third Industrial Revolution (1960s–1990s)

Computers, semiconductors, digital control systems, and the internet reshaped industry with programmable logic controllers (PLCs) and automation technologies.

4. Industry 4.0 (2000s–present)

The newest revolution builds on digitalisation but goes further—integrating intelligent systems, real-time data, machine learning, and decentralised decision-making.

Nicola Accialini highlights that industry 4.0 responds to modern challenges such as:

-

higher productivity requirements

-

increasing efficiency demands

-

faster decision-making

-

mass customisation

-

higher transparency

-

cost optimisation

While earlier revolutions replaced manual labour with machines, industry 4.0 focuses on making machines smarter and more connected.

For global context, the World Economic Forum outlines how the fourth industrial revolution merges digital, physical, and biological technologies.

Key Benefits of Industry 4.0

Accialini identifies one central outcome: better information leads to better decisions.

But the benefits extend across many operational areas.

1. Higher Productivity

Connected systems collect real-time production data, enabling automated adjustments and continuous optimisation.

2. Flexibility in Manufacturing

Companies can switch between product variations more easily and respond faster to customer needs.

3. Automation and Self-Configuring Machines

Machines learn from data, tune their own parameters, and require less manual intervention. Employees become supervisors rather than operators.

4. Predictive Capabilities

Predictive maintenance, demand forecasting, and quality prediction allow companies to act early rather than react to problems.

5. Financial Transparency

Digital systems can predict cash flow needs, inventory requirements, and cost structures more accurately.

6. Improved Resource Efficiency

Less waste, fewer errors, and better use of machines and materials.

Industry 4.0 is not about technology for its own sake—it is about making production intelligent, stable, and scalable.

How Companies Implement Industry 4.0

Accialini describes implementation as a process of transforming a traditional business into a smart company. Implementation does not mean buying every available technology. Instead, it means integrating digital tools strategically to solve specific problems.

Examples of Industry 4.0 implementation:

-

sensors for machine monitoring

-

predictive maintenance to prevent breakdowns

-

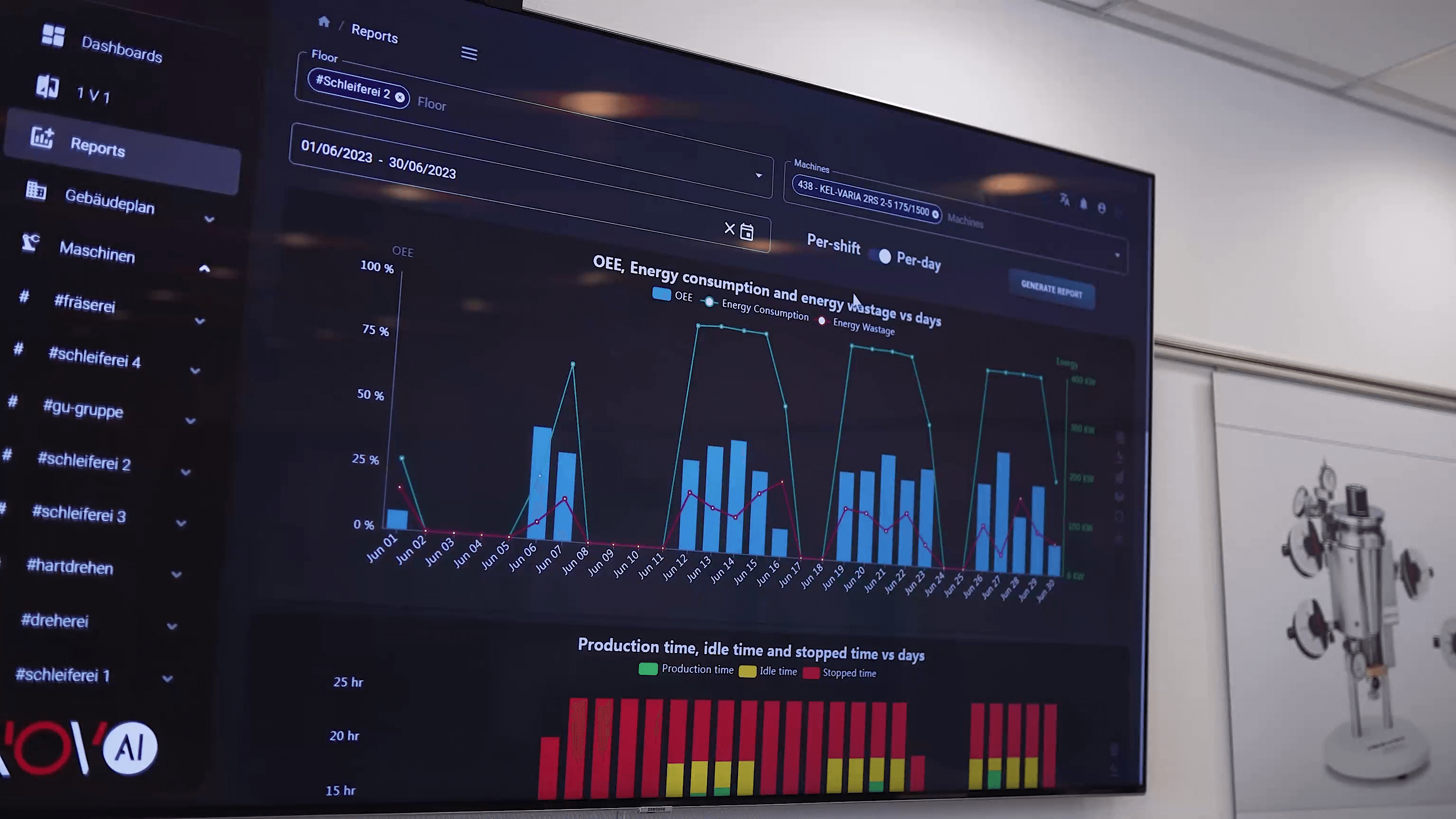

real-time dashboards showing the status of equipment

-

cloud platforms for data accessibility

-

AI systems for quality prediction

-

robotics and automation

-

digital twins for product and process simulation

-

augmented or virtual reality for training and assembly guidance

The goal is to connect machines, systems, and people while enabling real-time decision-making.

Accialini emphasises that companies gain a competitive advantage by predicting machine behaviour rather than reacting after failures occur.

How Much Does Industry 4.0 Cost?

The cost varies widely depending on the level of automation and digitalisation.

Some technologies—like sensors—are relatively inexpensive. Others—like robotics, 3D simulation environments, or digital twins—require more investment.

Accialini stresses that the main barrier is not financial but psychological.

Employees often resist adopting new tools when they do not understand how they work. Successful implementation requires:

-

openness to change

-

training and upskilling

-

leadership commitment

-

clear communication

-

demonstration of early wins

Technology becomes affordable; mindset change must follow.

Managing Big Data and Privacy in Industry 4.0

As machines become interconnected, companies must handle large volumes of industrial data responsibly. Privacy concerns arise, especially in B2B environments where sensitive operational information is shared.

Accialini notes that governments must create appropriate rules to ensure safe data usage. Regulations must adapt continuously as technology evolves. Companies need clear standards for:

-

data protection

-

secure data sharing

-

system interoperability

-

machine-to-machine communication

-

safe analytics practices

Big Data becomes useful only when legal frameworks and trust are in place.

Why Companies Must Embrace Industry 4.0

In private life, the benefits of technology adoption—smartphones, online learning, connected devices—are evident. Yet in companies, adoption often moves slower due to resistance, fear of complexity, or unclear return on investment.

Accialini argues that organisations must change their mindset. Industry 4.0 is not a trend; it is the new standard. Companies that adopt it early gain a clear advantage, while those that delay risk falling behind competitors who are already leveraging data and automation to improve performance.

Industry 4.0 is not optional. It is an essential evolution for companies that want to remain competitive in an increasingly digital and global marketplace.