Digital disruptions caused by unplanned downtime can significantly impact production. This can result in unexpected shutdowns or equipment failures that can occur at any time. It is costly in many aspects of manufacturing and requires significant time and money to fix. According to an estimation in 2017 by Deloitte, a factory may lose overall productivity by 5% to 20%. Another study from Emerson found that the most common cause of unplanned downtime is equipment failure, which accounts for 42% of all unplanned downtime. Unplanned downtime is an ongoing problem in the manufacturing industry. To combat it, the solution is very crucial in terms of efficiency and cost savings.

Prevent Downtime with IoT Sensors and Predictive Analytics

Achieving unplanned downtime goals requires finding the right technology. The ultimate goal is to anticipate malfunctions and proceed with maintenance operations proactively. The implementation of procedures takes time within a business. The first step is to detect potential issues and fix them before a shutdown may occur. The fastest way to find problems is through continuous access to machine health data and identifying anomalies. Internet-connected sensors are the solution. They can continuously measure the condition of the machine and transfer data over a network without human interaction.

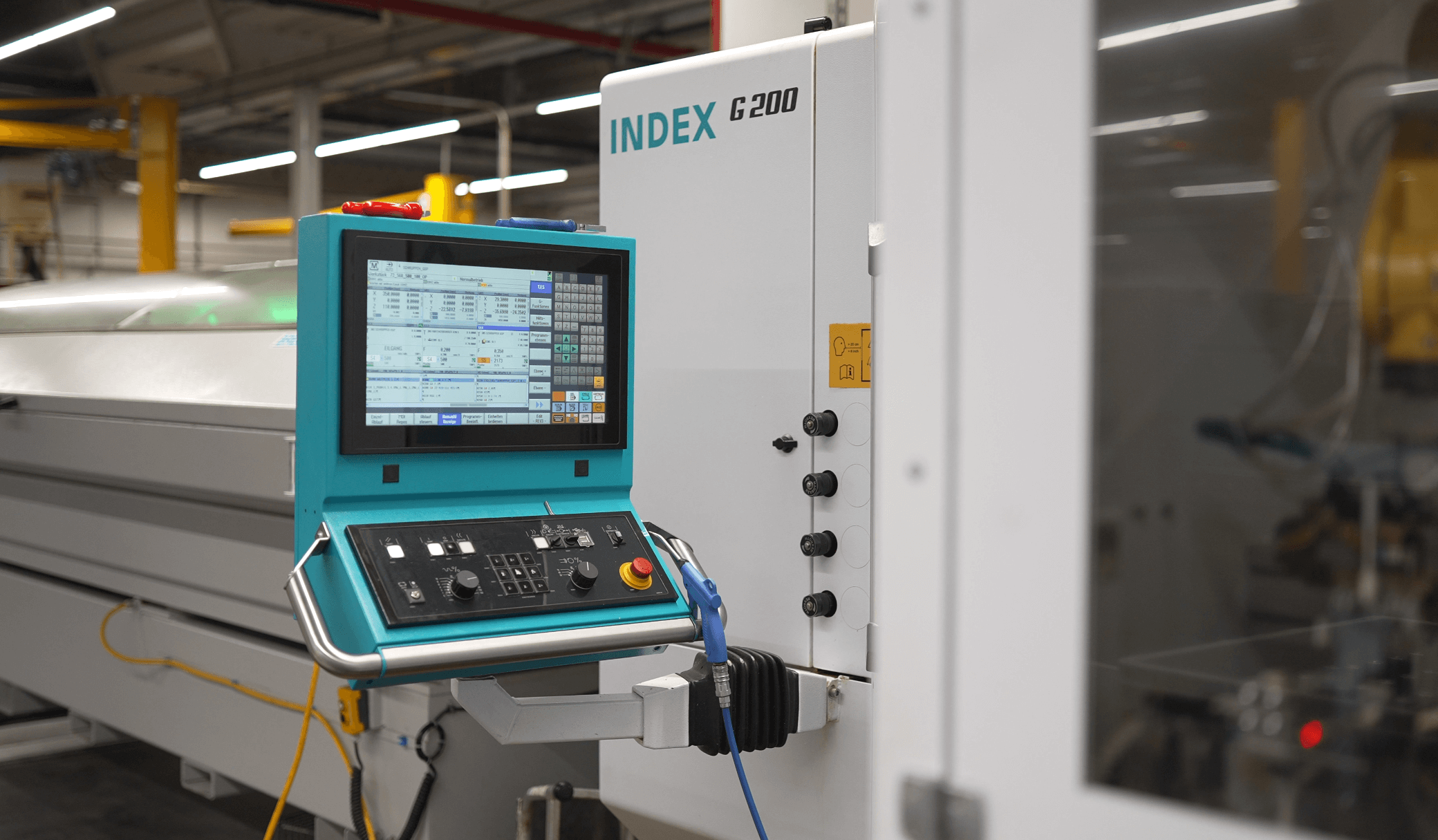

IoT sensors are attached to the machines and can capture performance indications and machine health data in real-time. It sends data to cloud IoT platforms. The data is then fed into a predictive analytics platform that has the ability to process and analyze data. It can detect potential issues and send alerts to technicians. The whole system can collect and process a huge volume of data in real-time which provides instant access to the production process. It helps to improve the maintenance process and remove inefficiencies from the production process.

NOVO AI’s Digital Solutions

NOVO AI is offering AVa, an I-IOT signal sensor that monitors machine performance data. It can detect anomalies in critical machine parts and forecast their maintenance status. Furthermore, it then sends data to the cloud via Wi-Fi.

Our platform, “Watchman,” is designed to process and analyze data in the cloud. The result information is customized and displayed on the so-called “Watchman Dashboard.” The platform provides the user with thorough access to the real-time status of machines in production. Making decisions on time is extremely important.