AI Machine Monitoring: How AI Transforms Predictive Maintenance

Artificial intelligence has become a defining technology for modern manufacturing. As factories generate more data than ever before, companies need intelligent tools capable of interpreting this information and transforming it into actionable insights. AI machine monitoring is one of the most impactful developments in this space. It brings together machine learning, real-time data analysis, and predictive algorithms to help manufacturers reduce downtime, extend equipment life, and improve process reliability.

Traditionally, maintenance teams fixed machines only after failures occurred or scheduled inspections at regular intervals. But reactive and static maintenance strategies often lead to costly breakdowns, unnecessary downtime, and inefficient resource utilization. With AI machine monitoring, organizations can transition from reactive maintenance to predictive and proactive decision-making—anticipating problems before they disrupt production.

This article explores how AI and machine learning enhance machine monitoring, the different predictive models used, and the practical benefits AI brings to manufacturing environments.

Understanding AI and Machine Learning in Machine Monitoring

Artificial intelligence replicates certain aspects of human decision-making by learning from patterns in data. Machine learning—one of the core components of modern AI—focuses on training algorithms to analyze large sets of information and identify trends, correlations, and anomalies without being explicitly programmed for every scenario.

Leading technology organizations, such as IBM, describe machine learning as a method that enables systems to learn from experience and improve automatically.

When applied to industrial equipment, AI machine monitoring uses machine learning techniques to:

-

interpret real-time sensor data

-

detect abnormal behavior

-

forecast equipment failures

-

optimize maintenance timing

-

reduce operational disruptions

Instead of manually reviewing logs or waiting for breakdowns, AI-based systems continuously evaluate the health of machines and alert teams to potential issues before they escalate.

Why Predictive Maintenance Requires AI Machine Monitoring

Reactive maintenance—responding only after equipment fails—can be extremely costly. Unplanned downtime disrupts production schedules, compromises product quality, and often requires expensive emergency repairs. Even preventive maintenance has limitations: performing maintenance too early wastes time and resources, while performing it too late risks severe damage.

Machine monitoring solves these issues by enabling predictive maintenance. Through machine learning and time-series analysis, AI models can learn failure patterns and identify the earliest indicators of malfunction.

By continuously analyzing data such as vibration, temperature, humidity, pressure, and density, AI systems can estimate:

-

how much useful life remains in a component

-

when failure is likely to occur

-

how abnormal a machine’s current behavior is

-

which subsystems are degrading fastest

-

what combination of signals precedes breakdowns

These insights allow manufacturers to take action precisely when it is needed, not based on guesswork or fixed schedules.

Machine Learning Models Used in AI Machine Monitoring

AI machine monitoring relies on different types of machine learning models depending on the prediction goal. These models help maintenance teams understand the condition of equipment, anticipate failure events, and minimize downtime.

1. Regression Models for Remaining Useful Life (RUL)

Regression algorithms forecast how many days or cycles remain before a machine or component fails.

They rely on:

-

historic maintenance records

-

real-time condition data

-

environmental factors

-

aging patterns

Predicting RUL helps companies:

-

schedule maintenance proactively

-

reduce the risk of unexpected breakdowns

-

avoid premature replacement of parts

By accurately estimating service life, regression-based AI models optimize both performance and cost efficiency.

2. Classification Models for Failure Prediction

Classification algorithms determine whether a failure is likely to occur within a specified time window—for example, within the next 5, 10, or 20 days.

These models categorize machine conditions into states such as:

-

normal

-

warning

-

imminent failure

This simplifies decision-making for maintenance teams, allowing them to prioritize equipment that needs attention.

3. Anomaly Detection Models

Anomaly detection models identify unusual patterns in machine behavior by comparing real-time data to learned normal behavior.

They detect:

-

sudden shifts in vibration

-

irregular temperature fluctuations

-

abnormal energy usage

-

deviations in cycle time

Anomaly detection is especially valuable when failure patterns are complex or when labeled failure data is limited. AI machine-monitoring systems using anomaly detection can recognize subtle changes long before a catastrophic failure.

The Power of Time-Series Data in AI Machine Monitoring

Time-series data—measurements collected over time—is the foundation of predictive maintenance. Machine learning models trained on continuous data streams can detect long-term trends and short-term fluctuations that signal emerging issues.

Common time-series inputs include:

-

temperature spikes

-

vibration harmonics

-

torque variations

-

humidity shifts

-

energy consumption patterns

-

operating cycle inconsistencies

The ability to interpret these patterns is what makes AI machine monitoring far more powerful than traditional methods. Humans may miss gradual changes or complex correlations, but machine learning models can detect them instantly.

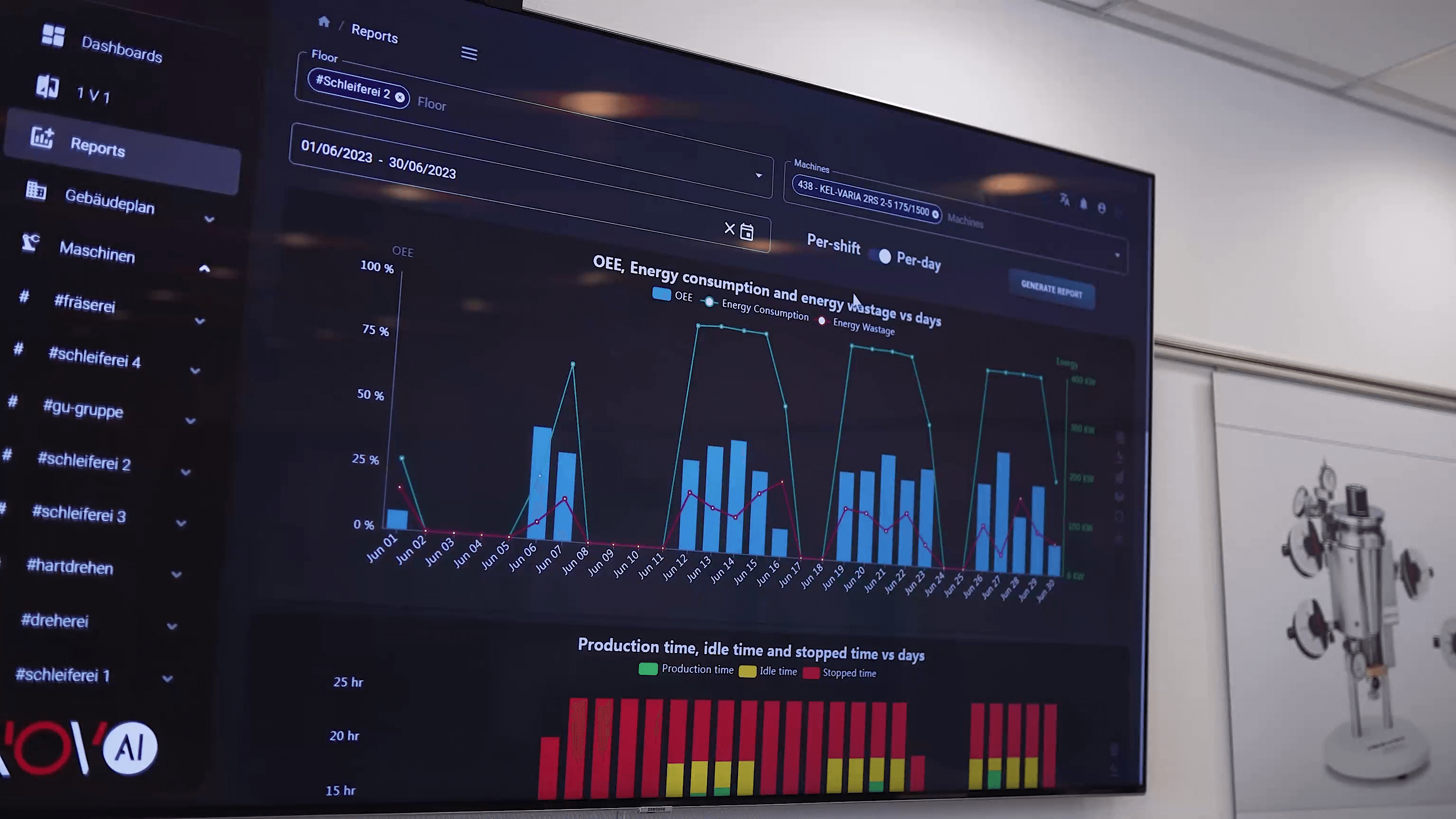

Advantages of AI Machine Monitoring in Modern Manufacturing

1. Increased Accuracy in Failure Prediction

AI-driven monitoring significantly improves prediction accuracy compared to manual evaluation or static maintenance intervals.

This accuracy reduces:

-

false alarms

-

unnecessary maintenance

-

unexpected breakdowns

2. Early Warning for Hidden Problems

AI identifies subtle deterioration that humans cannot easily detect.

This enables intervention before equipment reaches critical failure.

3. Reduced Downtime

By predicting failure timing, companies can plan maintenance during low-impact periods.

This minimizes production interruptions.

4. Lower Maintenance Costs

AI reduces the frequency of unnecessary maintenance tasks and prevents costly catastrophic failures.

5. Longer Equipment Lifespan

Continuous monitoring and targeted maintenance help equipment operate more efficiently for a longer time.

6. Higher Safety and Reliability

Detecting problems early reduces hazardous situations and improves overall production stability.

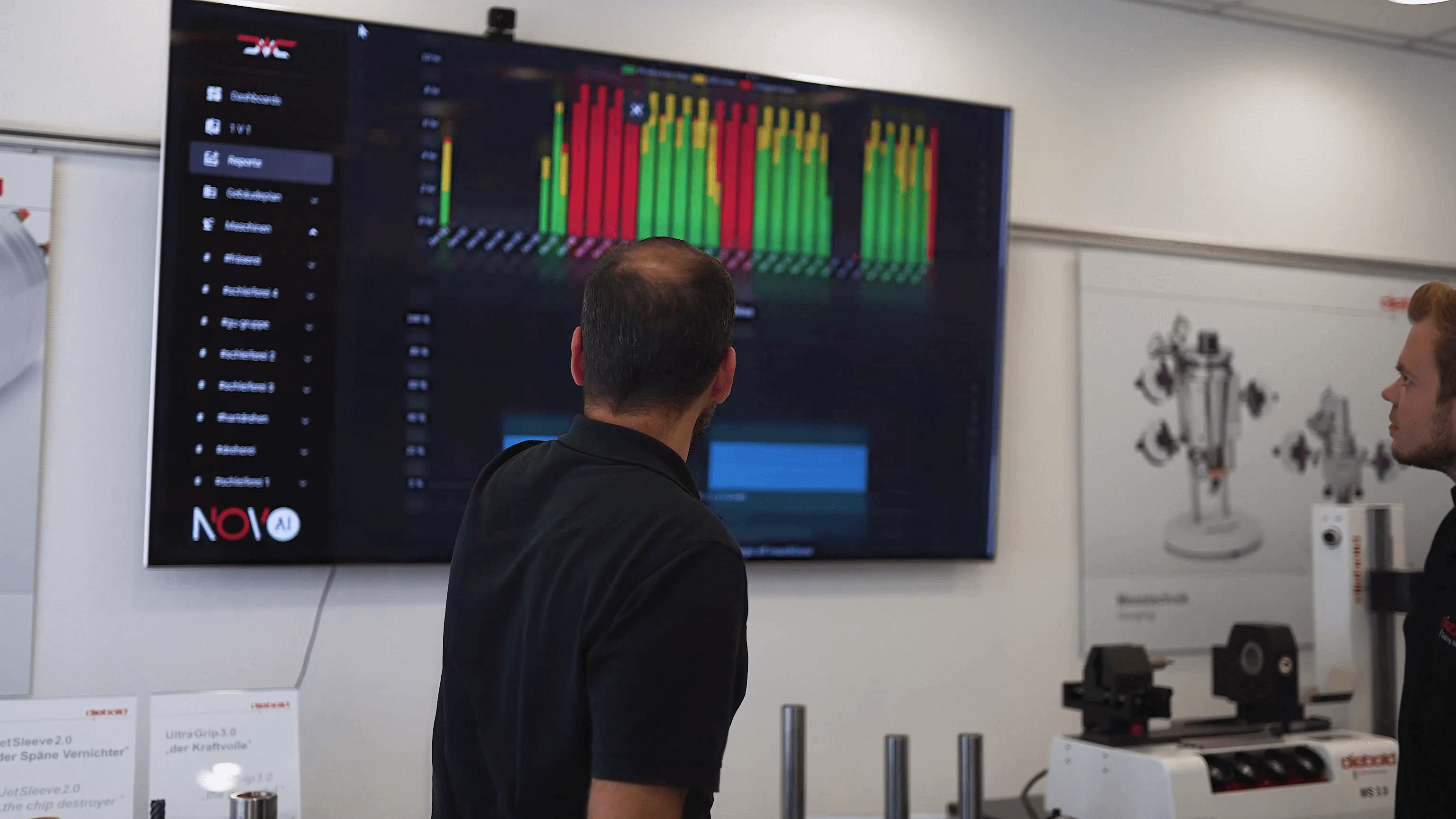

7. Enhanced Decision-Making

Real-time dashboards and AI-generated insights allow maintenance teams to act confidently and strategically.

Industry leaders like Siemens emphasize how AI enhances industrial reliability and performance through intelligent analytics.

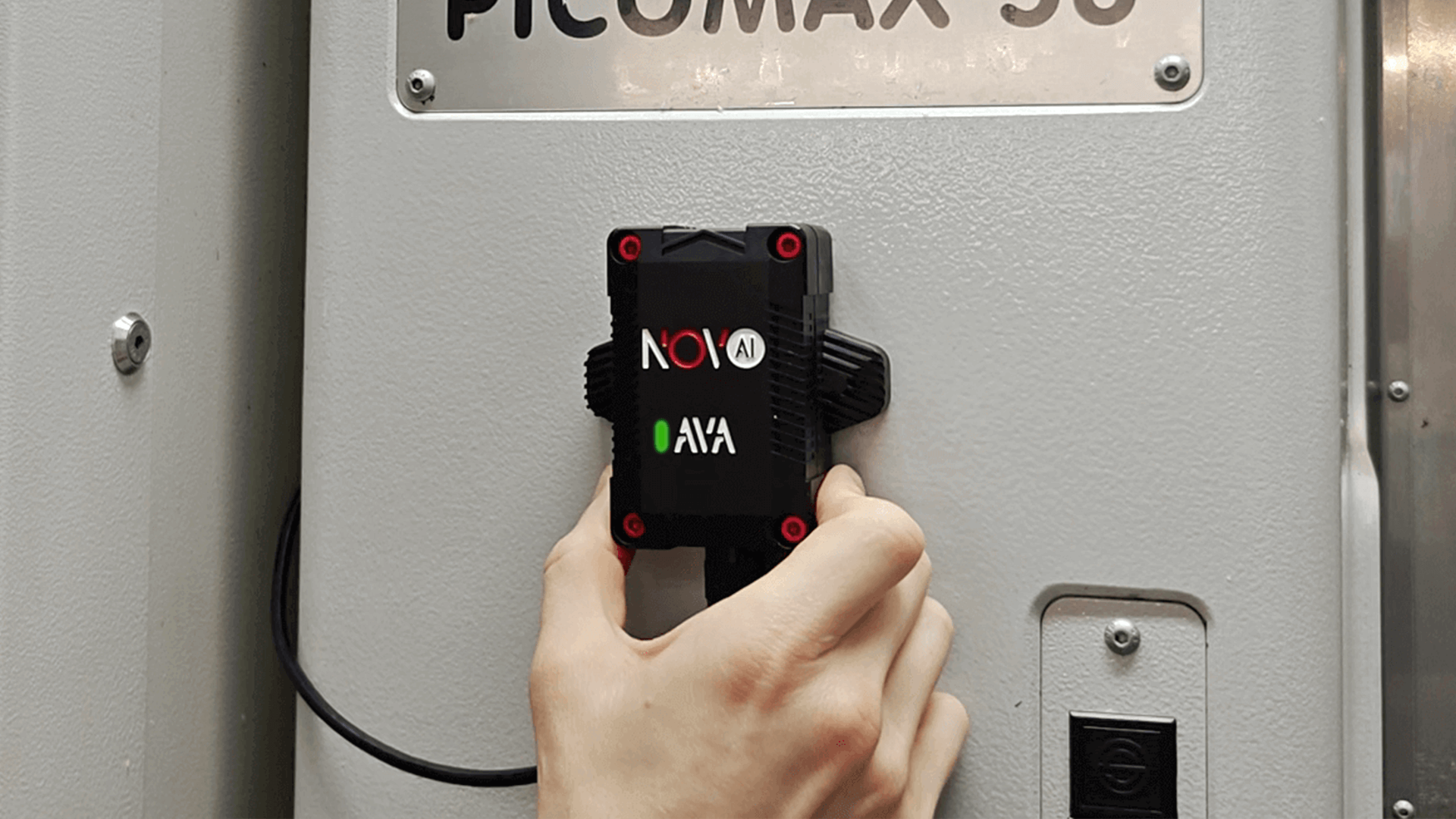

Machine Monitoring as a Key Technology for Industry 4.0

The rise of Industry 4.0 has turned AI from an optional upgrade into a strategic necessity. With greater automation, higher speeds, and growing system complexity, traditional monitoring methods are no longer enough.

AI machine monitoring supports Industry 4.0 by:

-

enabling autonomous machine-health assessment

-

integrating with digital twins

-

strengthening predictive maintenance

-

improving energy efficiency

-

supporting continuous optimization

-

reducing human dependency for monitoring tasks

As manufacturers adopt more robots, CNC machines, modular systems, and interconnected production lines, AI ensures that all components operate harmoniously and efficiently.

Why Companies Should Adopt AI Machine Monitoring Now

Organizations that implement AI machine monitoring gain immediate and long-term benefits:

-

better visibility into machine condition

-

smoother workflows

-

higher overall equipment effectiveness (OEE)

-

fewer production disruptions

-

improved quality consistency

-

more accurate maintenance planning

In contrast, companies that rely solely on human monitoring or fixed maintenance schedules risk:

-

frequent unplanned downtime

-

higher operating costs

-

reduced competitiveness

AI machine monitoring does not eliminate the need for human experts. Instead, it enhances their work with reliable, data-driven insights that improve decision-making and operational outcomes.

Conclusion: AI Machine Monitoring Is Essential for the Future of Manufacturing

Artificial intelligence is redefining industrial monitoring and maintenance strategies. By analyzing time-series data, detecting anomalies, predicting failures, and optimizing maintenance timing, AI machine monitoring offers manufacturing companies a powerful tool to increase reliability, reduce downtime, and operate more efficiently.

Regression models, classification algorithms, and anomaly detection systems each contribute to a more intelligent, proactive approach to machine-health management. With the help of AI-driven monitoring, organizations can avoid disruptions, extend the lifespan of equipment, and transition confidently into the era of smart manufacturing.

As Industry 4.0 evolves, AI machine monitoring will remain at the center of modern production strategies—ensuring that factories run more safely, efficiently, and predictably than ever before.