Optimize Manufacturing: How AI and Advanced Analytics Transform Modern Production

Artificial intelligence is rapidly reshaping global industry, and nowhere is this transformation more visible than in manufacturing. As factories become increasingly digitalized and data-rich, organizations are discovering how powerful analytics and intelligent algorithms can be in reducing costs, improving throughput, minimizing delays, and strengthening operational resilience.

McKinsey reports that over 60% of manufacturers using AI have already achieved measurable cost reductions across production, supply chain management, maintenance, and quality. For many companies, AI is no longer a futuristic concept—it's the most effective way to optimize manufacturing in a competitive global landscape.

The rise of Industry 4.0, together with machine learning (ML), Big Data, and IIoT (Industrial Internet of Things), is enabling manufacturers to extract value from the massive streams of information produced on the shop floor. Production plants generate huge volumes of data daily—far more than humans can manually interpret. AI and ML thrive in precisely these environments, uncovering insights that lead directly to efficiency gains, higher reliability, and reduced operational costs.

This article explores how organizations can optimize manufacturing using AI-driven forecasting, scheduling, analytics, and predictive maintenance. It examines practical use cases that demonstrate how intelligent systems help manufacturers achieve higher performance with their existing resources.

Why AI Has Become a Cornerstone for Optimizing Manufacturing

Modern supply chains and production environments are too complex for traditional planning approaches. Manufacturing leaders now face:

-

volatile customer demand

-

tight delivery windows

-

energy cost fluctuations

-

equipment aging and failure risks

-

globalized supply networks

-

labor shortages

-

rising raw material costs

To optimize manufacturing effectively, companies must base decisions on real-time data—not intuition, spreadsheets, or outdated processes.

According to insights published by the World Economic Forum, digitally advanced manufacturers achieve higher resilience and productivity because data-driven systems allow them to adjust faster to uncertainty.

AI thrives under these conditions. With access to enormous data sets, AI systems can identify inefficiencies, optimize manufacturing workflows, and anticipate issues before they disrupt production.

Analytics Technology: The Foundation for Optimized Manufacturing

Supply Chain Dive highlights that manufacturers increasingly rely on analytics technologies to improve yield, reduce energy consumption, increase throughput, and maximize asset performance. These improvements stem from two major capabilities powered by AI:

-

Network optimization

-

Forecasting improvements

Together, these capabilities help optimize manufacturing by enabling planners to predict bottlenecks, adjust capacity, and prepare for future constraints. Instead of reacting to problems after they occur, planners make decisions proactively.

When AI supports forecasting, manufacturers experience:

-

fewer material shortages

-

fewer overstocks

-

better production timing

-

improved on-time delivery

-

reduced emergency shipments

-

higher customer satisfaction

Improved accuracy translates into lower unit costs and more efficient use of capital.

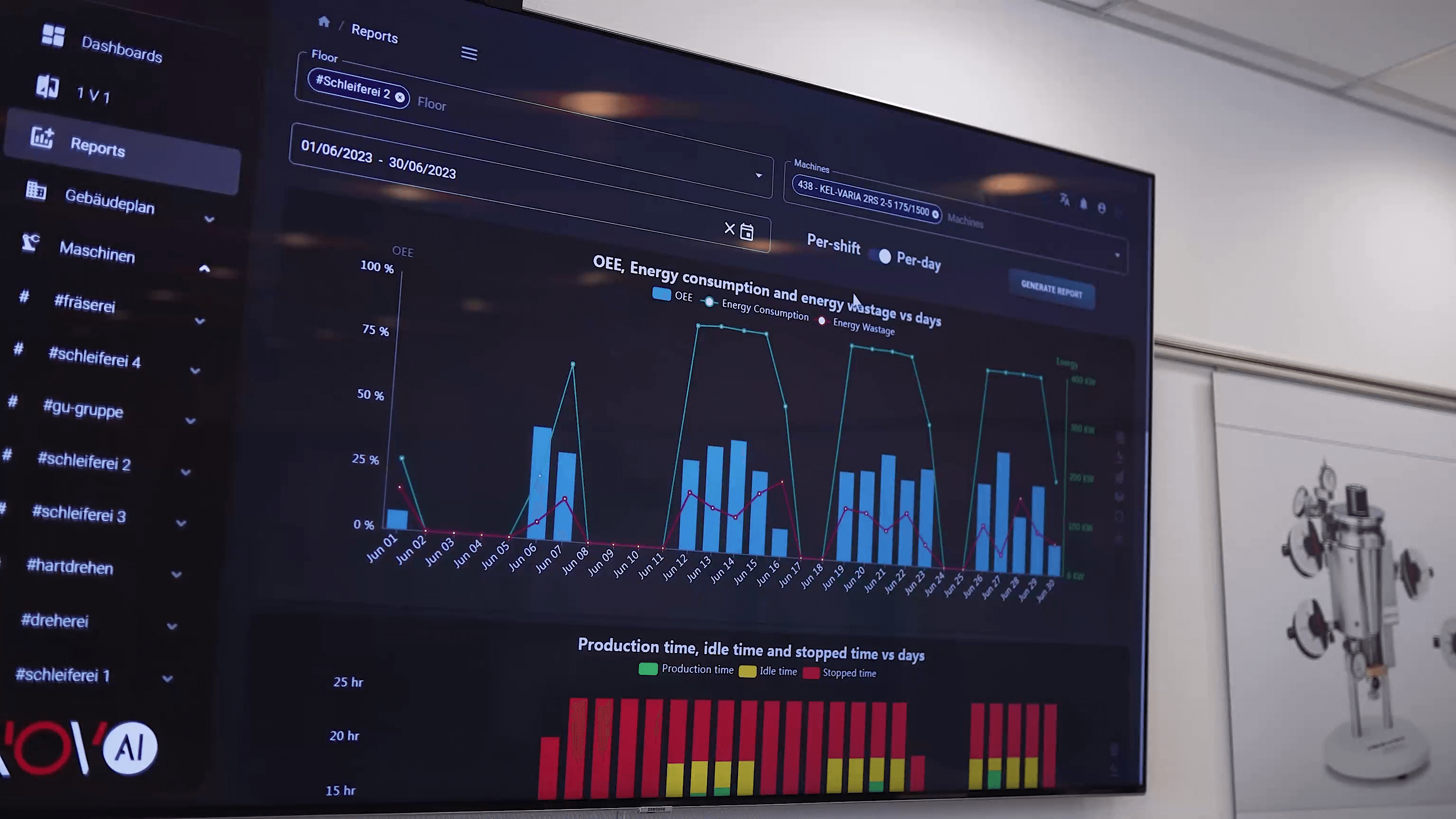

Detailed Scheduling: The Practical Way AI Optimizes Manufacturing

Forecasting provides the foundation, but the real test of AI’s value happens on the shop floor—where production plans must be executed with precision.

Detailed scheduling is one of the most powerful ways to optimize manufacturing with AI.

Production scheduling requires considering:

-

machine availability

-

labor shifts and skill sets

-

maintenance windows

-

raw material deliveries

-

order priorities

-

cycle times

-

setup and changeover duration

-

batching requirements

-

energy usage patterns

A human planner attempting to account for all these constraints manually is easily overwhelmed. Even digital planning tools without AI often fail to generate truly optimal schedules, because they cannot consider the full complexity of dependencies involved.

AI-powered scheduling tools, however, can:

-

evaluate thousands of scheduling scenarios in seconds

-

optimize production sequences for minimal changeover time

-

align schedules with material availability

-

reduce idle time

-

increase overall equipment effectiveness (OEE)

-

improve on-time delivery performance

By optimizing manufacturing runs at this granular level, AI enables planners to respond faster to customer orders, production delays, material shortages, or machine breakdowns.

Manufacturers not only gain efficiency—they gain agility.

Predictive Machine Maintenance: AI’s Biggest Operational Advantage

Forecasting demand and optimizing schedules are crucial, but optimized manufacturing collapses instantly when equipment fails unexpectedly. Machine breakdowns are among the most expensive disruptions in production.

Unplanned downtime leads to:

-

rising unit costs

-

missed delivery dates

-

overtime labor

-

machine damage

-

lower OEE

-

emergency logistics costs

Predictive maintenance—powered by AI—directly addresses this challenge.

How predictive maintenance works

AI models analyze real-time machine signals such as:

-

vibration

-

temperature

-

pressure

-

spindle load

-

energy patterns

-

acoustic anomalies

Instead of waiting for machines to fail, AI correlates these signals with historic breakdown patterns. As confirmed by research from MIT Sloan School of Management, AI-enabled maintenance systems significantly improve operational reliability by predicting failures early.

AI then alerts planners when an issue is likely to occur, allowing maintenance teams to:

-

repair equipment during planned downtime

-

prevent cascading failures

-

extend machine lifespan

-

stabilize production capacity

This shifts maintenance strategy from reactive to fully proactive—one of the most effective ways to optimize manufacturing and reduce operational waste.

Real-Time Monitoring: A Continuous Engine for Optimization

Real-time monitoring is the connective tissue that integrates AI with manufacturing operations. Continuous data streams allow AI to:

-

identify developing issues

-

recommend process adjustments

-

spot inefficiencies

-

support energy optimization

-

detect abnormal patterns

-

adjust scheduling dynamically

This live operational visibility is what empowers AI to optimize manufacturing processes across multiple layers:

-

line-level optimization

-

machine-level diagnostics

-

throughput analysis

-

quality pattern detection

-

material flow optimization

Manufacturers can react instantly—not hours or days later.

How AI Transforms Cost Structure and Resource Utilization

AI does not only optimize manufacturing; it transforms the economics of production.

1. Reduced Downtime

Predictive maintenance and real-time monitoring drastically cut unexpected downtime, which is a major cost driver.

2. Increased Throughput Without Additional Equipment

More efficiency = more output from the same assets.

3. Lower Energy Costs

AI identifies energy-intensive patterns and suggests optimizations for off-peak hours.

4. More Accurate Labor Planning

With better forecasting and scheduling, companies balance workforce levels with actual workload.

5. Reduced Material Waste

AI can detect quality deviations early enough for corrective action.

6. Better Use of Capital Commitments

Optimized manufacturing means fewer unnecessary equipment purchases and better ROI from existing assets.

Why AI Is Essential for Staying Competitive

AI is no longer optional. Companies that adopt it can optimize manufacturing at a level not achievable with traditional tools. They adapt faster, operate more efficiently, and deliver higher-quality products with greater consistency.

As global supply chains become more unpredictable and customer expectations grow, optimizing manufacturing with AI becomes a strategic requirement—not a luxury.

Conclusion: AI Is the Key to Optimized Manufacturing in the Future

AI allows companies to optimize manufacturing by combining forecasting, scheduling, real-time monitoring, and predictive maintenance into a single, intelligent ecosystem.

It reduces waste, minimizes downtime, improves throughput, enhances planning accuracy, and lowers production costs. As Industry 4.0 evolves, manufacturers that adopt AI will lead the next industrial transformation, while those who resist will struggle to remain competitive.