Improve Production With AI: How AI Reduces Human Error & Enhances Reliability

Manufacturing is becoming increasingly complex, and production reliability is now one of the most important competitive factors for industrial companies. When failures occur, they are often costly, disruptive, and in many cases preventable. Despite technological progress, many production environments still depend heavily on human monitoring and manual decision-making. But humans, by nature, have limitations: they cannot monitor countless signals simultaneously, they may overlook subtle warning signs, and their interpretations often depend on experience, intuition, or incomplete information.

In this context, companies worldwide are looking for ways to improve production with AI and overcome the constraints of human supervision. Artificial intelligence enables continuous monitoring, rapid pattern recognition, and highly accurate forecasting of failures. As production systems grow more advanced, improving production with AI becomes not only beneficial but essential.

This article explores how human error affects production, how AI transforms data management and maintenance, and why integrating AI improves production with AI-driven insights. The analysis includes independent research, industry findings, and real-world implications.

Why Human Error Remains One of the Biggest Risks in Manufacturing

When production relies solely on human oversight, issues often go undetected until they escalate into failures. Humans can only process a limited amount of visual, auditory, and numerical information at once. Even highly trained operators struggle to track dozens of machine indicators simultaneously—especially in facilities with complex equipment, tight schedules, and high throughput.

According to a study by Vanson Bourne, 23% of all production losses and unplanned downtime stem directly from human error. In fact, it was identified as the number one cause of downtime. The reasons are clear:

-

Humans cannot continuously monitor thousands of data points.

-

Warning signs may be subtle or invisible to the human eye.

-

Fatigue, stress, or distraction affect decision-making.

-

Complex systems require specialized knowledge many technicians do not have.

-

Error prediction becomes harder as production lines expand.

Manufacturing environments with diverse machinery, multiple control systems, and varied maintenance needs are especially vulnerable. Engineers and technicians frequently work under time pressure and with incomplete information. This creates ideal conditions for misdiagnosis, overlooked signals, and delayed problem detection.

As equipment ages, the likelihood of failure increases. Without accurate forecasting tools, many issues emerge “too late,” resulting in unplanned downtime, equipment damage, or costly emergency repairs. To remain competitive, companies must adopt more reliable methods to detect failures early and prevent them before they disrupt production.

Traditional Monitoring Methods: Valuable but Insufficient

Before the introduction of AI, companies relied on manual checks, operator experience, and periodic maintenance. While useful, these methods have clear limitations:

-

Manual inspections cannot detect constant changes.

Production conditions can vary minute-by-minute, far faster than scheduled inspections can capture. -

Maintenance intervals rely on estimates.

Machines may fail before planned maintenance—or be serviced too early, wasting resources. -

Human interpretation is subjective.

Technicians may interpret vibration patterns or temperature deviations differently depending on experience. -

Large data volumes overwhelm teams.

Sensors generate vast amounts of information that humans are not able to analyze holistically.

This leads to a critical gap: humans can sense that “something is off,” but they cannot reliably predict when failure will happen or what the root cause is. This is where improving production with AI becomes transformative.

Improving Production With AI: How AI Solves Human Limitation

Artificial intelligence is designed for exactly the kind of tasks humans struggle with:

processing huge data streams, recognizing complex patterns, and forecasting events before they occur.

1. AI Processes More Data Than Humans Can

Modern sensors measure:

-

vibration frequencies

-

acceleration patterns

-

temperature gradients

-

optical deviations

-

energy consumption

-

pressure fluctuations

-

operational cycles

A human may review a few trends at a time; AI can analyze millions of data points simultaneously.

This scale is one of the key ways of improving production with AI and enhancing reliability.

2. AI Detects Subtle Patterns and Anomalies

Many early warning signs are invisible to humans. AI models trained on historical and real-time data can identify deviations with remarkable precision, such as:

-

slight increases in vibration

-

micro-temperature spikes

-

irregular load changes

-

shifts in energy signatures

Research from the National Institute of Standards and Technology (NIST) confirms that AI-powered anomaly detection improves manufacturing accuracy and early failure recognition.

3. AI Predicts Failures Before They Happen

Predictive analytics is one of the most powerful tools for improving production with AI. It allows the system to:

-

evaluate machine health continuously

-

forecast potential failures days or weeks in advance

-

determine the exact time window for intervention

-

reduce the need for emergency repairs

-

optimize maintenance schedules

This prevents both unnecessary downtime and unnecessary maintenance, improving efficiency and lowering costs.

4. AI Reduces Human Error in Decision Making

AI does not replace technicians—but it gives them better information.

By interpreting sensor inputs at high speed, AI systems:

-

eliminate guesswork

-

provide confidence in maintenance decisions

-

reduce diagnostic errors

-

strengthen safety protocols

This empowers teams and enhances overall operational reliability.

5. AI Improves Safety and Production Efficiency

Improving production with AI leads to safer workflows because machines are checked continuously rather than sporadically. Early detection helps prevent:

-

overheating

-

mechanical fatigue

-

lubrication failures

-

alignment problems

-

excessive wear

All of these issues can develop quietly before resulting in sudden breakdowns.

The Key Role of Data Management: AI Makes Sense of Complexity

Even when humans do manage to collect sensor data, the challenge lies in interpreting it. Hundreds of charts, logs, and numerical streams require deep expertise and continuous focus to understand.

AI systems remove this burden by:

-

aggregating data

-

cleaning and structuring information

-

identifying relationships

-

detecting unusual patterns

-

highlighting emerging risks

According to research published by Harvard Business Review on AI-driven operations, companies that apply AI to industrial data experience higher accuracy in decision-making and greater resilience in production processes.

This demonstrates how AI improves production by turning raw information into actionable insights.

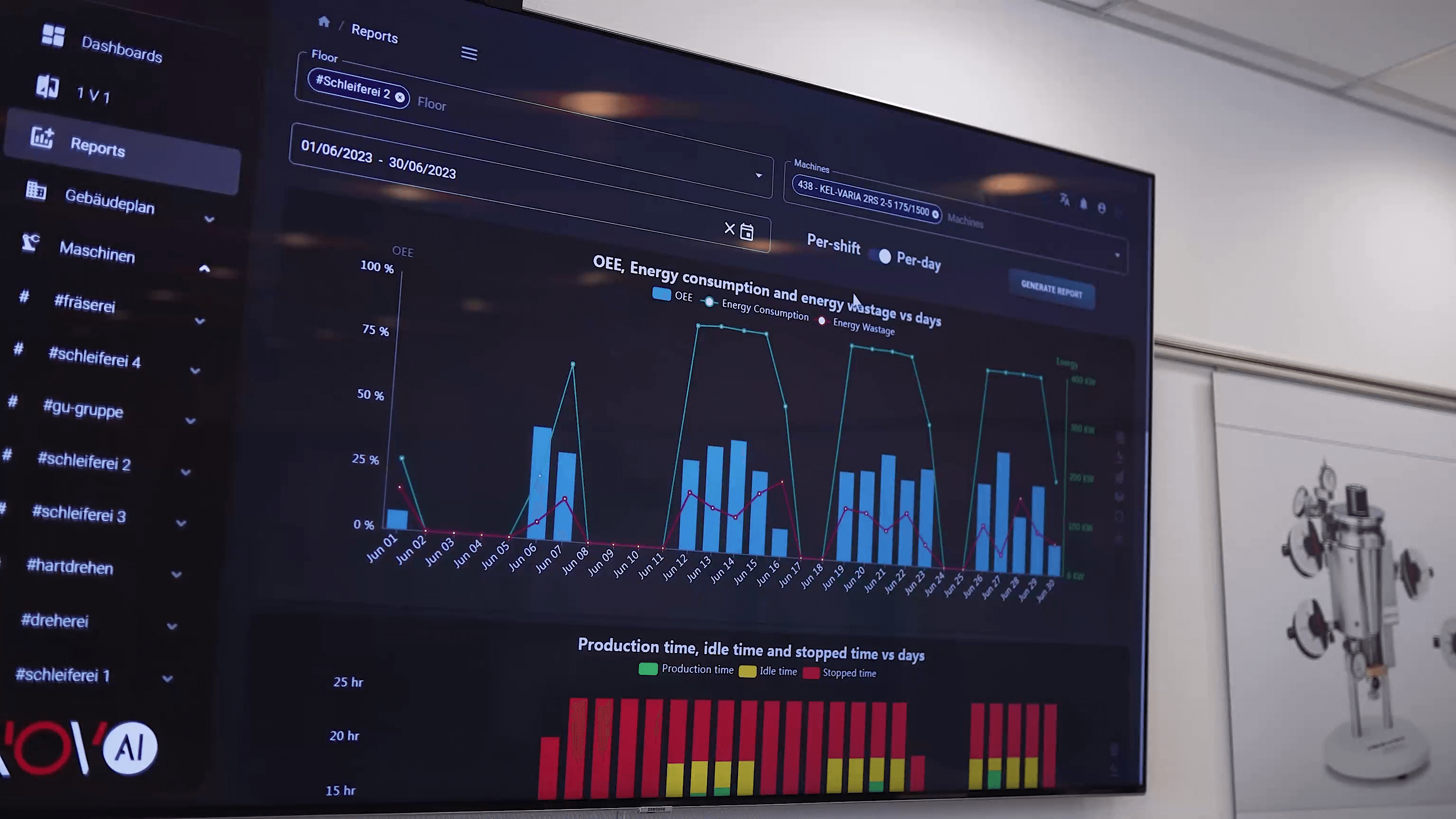

Improve Production With AI: Benefits for Modern Manufacturing

AI not only prevents failures but also strengthens operational performance. Companies using AI for reliability and maintenance experience multiple strategic advantages:

-

Higher OEE (Overall Equipment Effectiveness)

-

Greater production stability

-

Reduced scrap and quality deviations

-

Optimized resource management

-

Lower maintenance and labor costs

-

Faster root-cause analysis

-

Increased output with the same machinery

By transforming maintenance from reactive to predictive, AI also improves long-term equipment durability. Machines last longer, operate more efficiently, and require fewer emergency interventions.

AI becomes a competitive advantage, especially in industries where uptime is critical.

Technological Innovation: Why AI Adoption Is Essential for Industry 4.0

The evolution of Industry 4.0 demands continuous improvements in monitoring, automation, and decision-making. AI is at the center of this transformation. It elevates traditional methods with tools such as:

-

real-time data ingestion

-

deep learning anomaly detection

-

edge computing for fast on-site analysis

-

cloud-based dashboards

-

predictive maintenance algorithms

-

machine-to-machine communication

As factories digitalize, improving production with AI becomes a fundamental capability—not an optional upgrade.

Conclusion: Improve Production With AI to Build a Safer, Smarter Future

Human error has long been one of the most significant risks in production. As manufacturing grows more complex, relying solely on operator judgment is no longer sufficient. AI bridges this gap by monitoring machines continuously, analyzing vast data volumes, predicting failures early, and guiding maintenance with precision.

Companies that embrace AI improve production with AI-driven insights, reduce unplanned downtime, lower maintenance costs, enhance safety, and gain a long-term competitive advantage. Improving production with AI is not just a trend—it is a strategic necessity for organizations preparing for the future of automated manufacturing.