How IoT Sensors Give Old Machines New Life: Real-Time Data for a Smarter Factory

In today’s fast-paced industrial landscape, companies face constant pressure to increase efficiency, reduce downtime, and stay competitive. While many enterprises aspire to modernize their production environments, the reality is that a large portion of the machinery running in German factories is more than 10, 20, or even 30 years old. Replacing these machines is costly — and often unnecessary.

Thanks to modern IoT sensors, even decades-old equipment can be transformed into smart, data-driven assets. The combination of IoT, artificial intelligence and real-time analytics gives manufacturers the power to monitor, optimize and extend the life of their machines — without replacing them.

This article explores how sensors enhance industrial performance, why they are essential for connecting legacy machines, and how companies can overcome integration challenges to build a future-ready production system.

The Power of IoT Sensors in Industrial Modernization

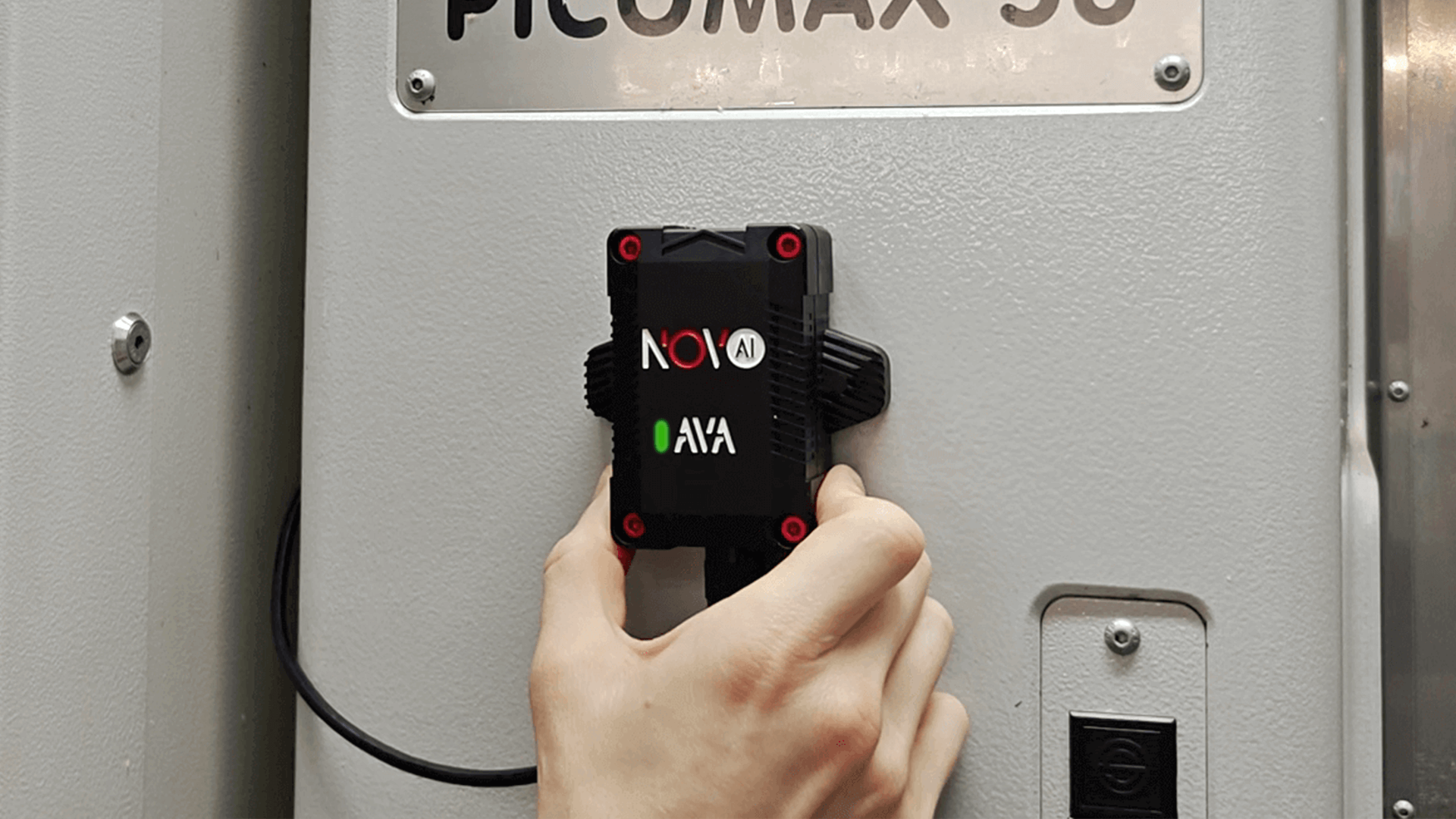

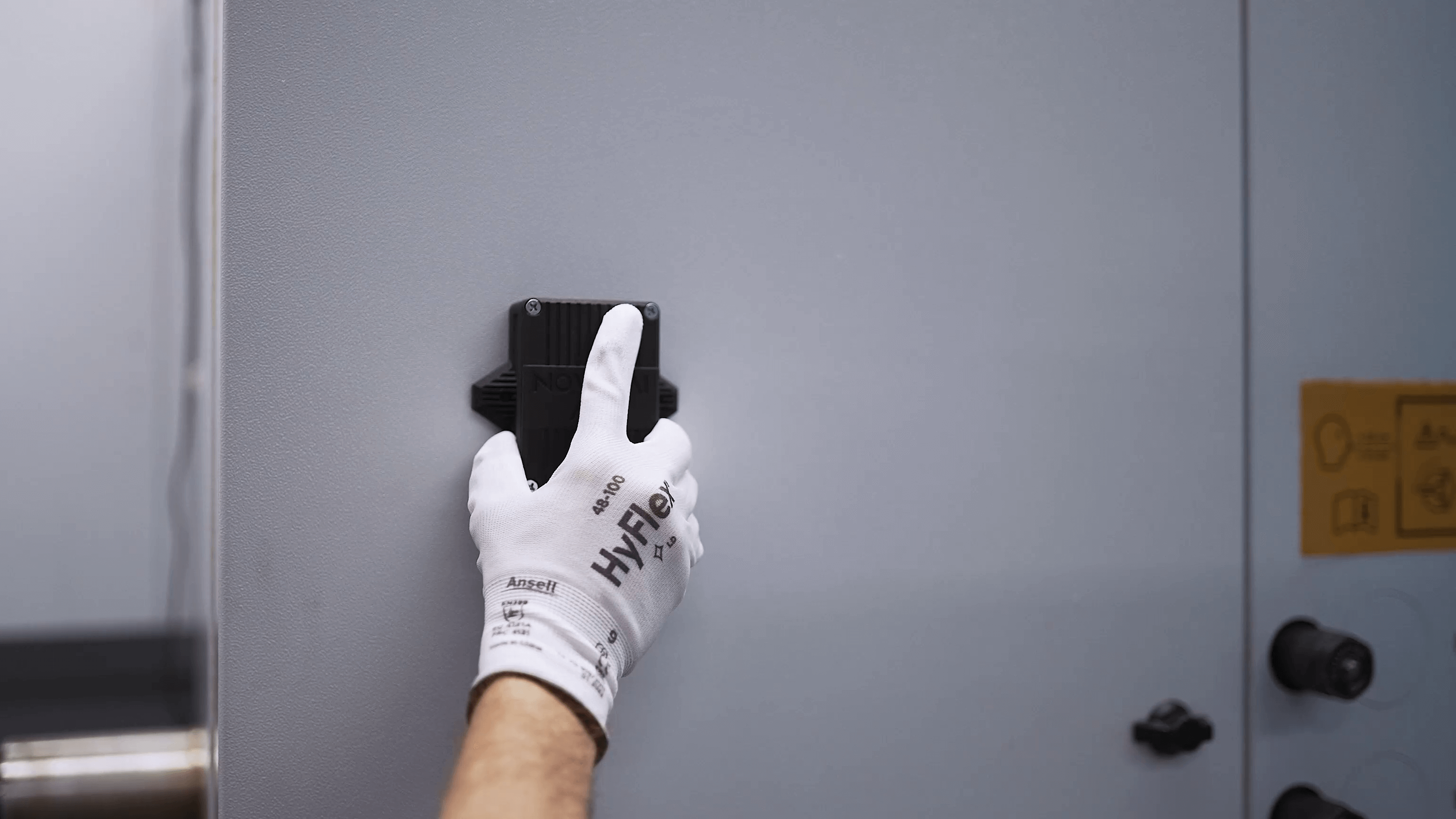

IoT sensors are small, intelligent devices capable of capturing machine signals such as vibration, temperature, energy consumption, acoustics and cycle patterns. When installed on older machines, they create a continuous flow of real-time operational data that was previously inaccessible.

These sensors provide companies with:

-

Condition-based monitoring

-

Cycle and performance tracking

-

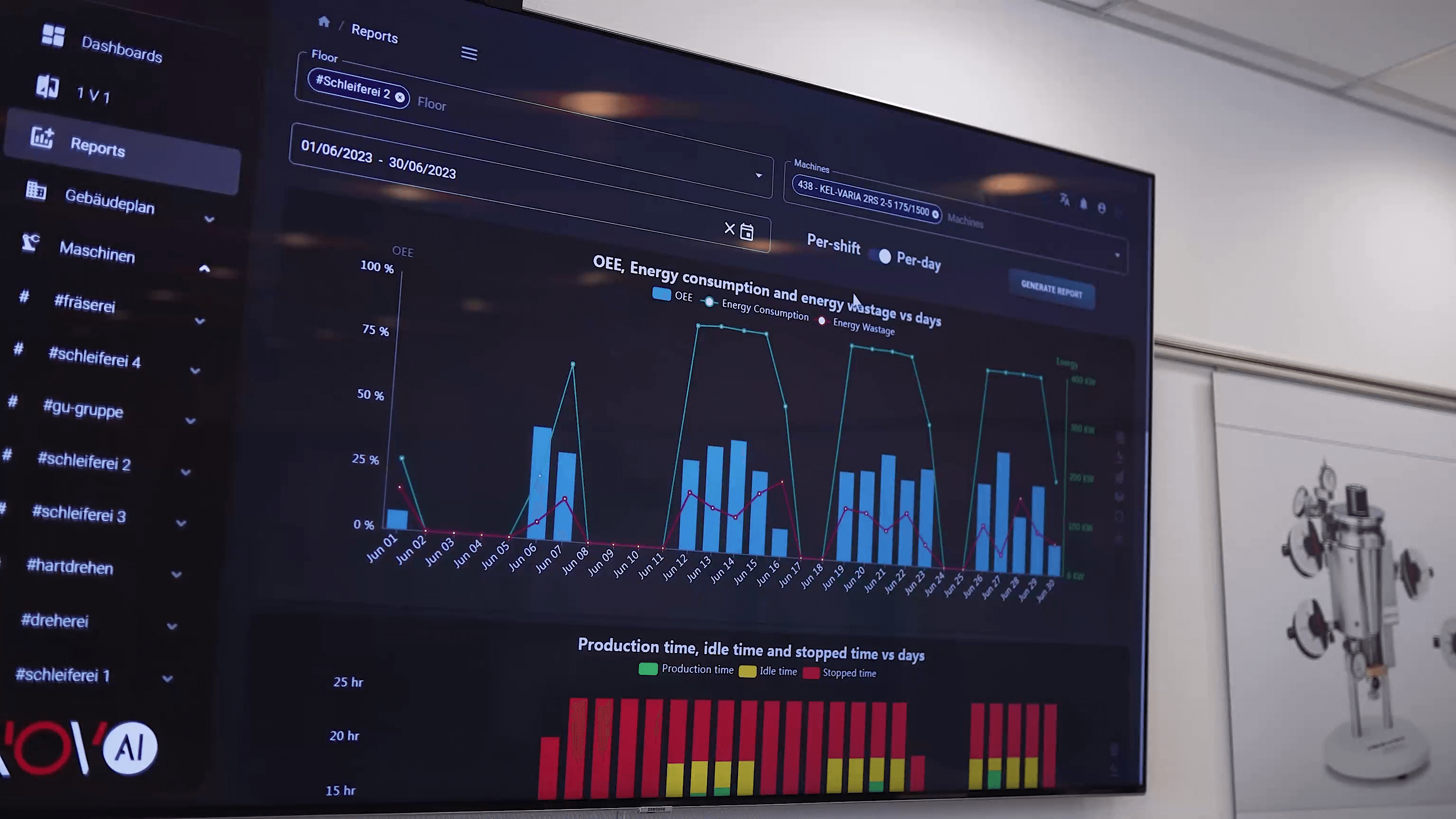

Accurate energy-consumption insights

-

Early detection of anomalies

-

Detailed productivity metrics

-

Predictive maintenance potential

According to PwC Germany, 41% of manufacturing executives already use IoT technologies to increase operational efficiency, and the trend continues to accelerate.

This shift shows that sensors are no longer optional — they are critical for industrial competitiveness.

Why Old Machines Benefit the Most From Sensors

Most older machines — press brakes, milling machines, lathes, extrusion lines, injection moulders — were never designed to communicate digitally. They operate reliably, but silently.

IoT sensors change this by giving old equipment a “digital voice”. Once a machine becomes measurable, everything changes:

1. Real-time visibility eliminates blind spots

Unplanned stoppages no longer remain unnoticed. IoT sensors detect vibration anomalies, acoustic changes or unusual cycle delays — often long before a failure occurs.

2. Predictive maintenance becomes possible

By analysing historical and live data, companies can detect early signs of mechanical wear.

Capgemini reports that 75% of German manufacturers are implementing or planning predictive maintenance via IoT sensors.

3. Resource efficiency increases automatically

When companies measure energy consumption by machine, shift, or production order, they identify waste and inefficiencies that would otherwise stay hidden.

4. Downtime decreases and machine life increases

Data-driven insights help teams intervene at the right moment — not too early, not too late.

5. No modification of the machine control system is necessary

External IoT sensors allow full transparency without opening the control cabinet, modifying PLC logic, or risking warranty issues.

This makes IoT sensors the ideal retrofit technology for industries with large legacy machine fleets.

IoT Sensors and the Role of Federated Learning

IoT sensors generate large volumes of machine data. Traditionally, this data would be sent to a cloud server for processing — but this creates bandwidth costs, privacy concerns and latency issues.

Federated learning solves this problem.

What is federated learning?

It is a machine-learning technique where the model is trained locally on decentralized devices — instead of sending all raw data to a central cloud.

This brings several benefits:

-

Higher data privacy (sensitive machine data stays on-site)

-

Lower communication costs

-

Faster reaction times

-

Reduced cybersecurity risks

-

More robust real-time analysis

In production environments where every millisecond counts, federated learning enables IoT sensors and AI systems to deliver instant insights.

Practical Advantages of IoT Sensors in Daily Operations

Industrial SMEs in Germany can achieve transformative operational improvements:

✔ Process transparency

Production teams finally see what the machine is doing — in real time.

✔ Downtime reduction

Anomalies are detected early. Teams intervene before breakdowns occur.

✔ Cycle and performance optimization

IoT sensors help identify bottlenecks, slowdowns and inefficient operator workflows.

✔ Energy savings and CO2 reduction

Live energy monitoring reveals inefficiencies and reduces wasteful standby times.

✔ Quality assurance

Acoustic and vibration signatures often reveal quality issues long before they appear in finished parts.

✔ Better strategic decisions

With accurate Maschinendaten (machine data), managers no longer rely on intuition alone.

Overcoming Challenges When Adding IoT Sensors to Old Machines

Despite the clear benefits, many companies hesitate due to perceived risks. Here are the most common challenges — and how to solve them:

1. No digital interface available

Most older machines lack OPC-UA or modern PLC communication.

Solution: External IoT sensors bypass the control system entirely.

2. Heterogeneous machine park

Different brands, different ages, different technologies.

Solution: Vendor-agnostic IoT sensors create a unified data layer.

3. Data security concerns

Industrial data is sensitive.

Solution: Federated learning and encrypted communication minimize exposure.

4. Fear of complex IT integrations

Not every company has an IT department.

Solution: Modern IoT sensors are plug-and-play and require minimal configuration.

5. Perceived high investment costs

Many expect IoT systems to be expensive.

Solution: Retrofit IoT sensors cost a fraction of a new machine and pay for themselves through downtime reduction.

A Future Built on IoT Sensors and Industrial Intelligence

Industry leaders worldwide agree:

IoT sensors are the backbone of the next industrial revolution.

When combined with machine learning, federated learning and edge AI, they enable factories to:

-

Operate more autonomously

-

Avoid unplanned downtime

-

Reduce operational waste

-

Improve product quality

-

Strengthen competitiveness

As Deloitte highlights, companies adopting AI-enhanced IoT ecosystems achieve significantly higher productivity and lower operational costs.

For SMEs, this is not merely an opportunity — it is a survival strategy. Those who fail to leverage IoT sensors risk falling behind global competitors who produce faster, cheaper and more intelligently.