Smart Factory: Core Principles, Industrial Impact, and System Architecture

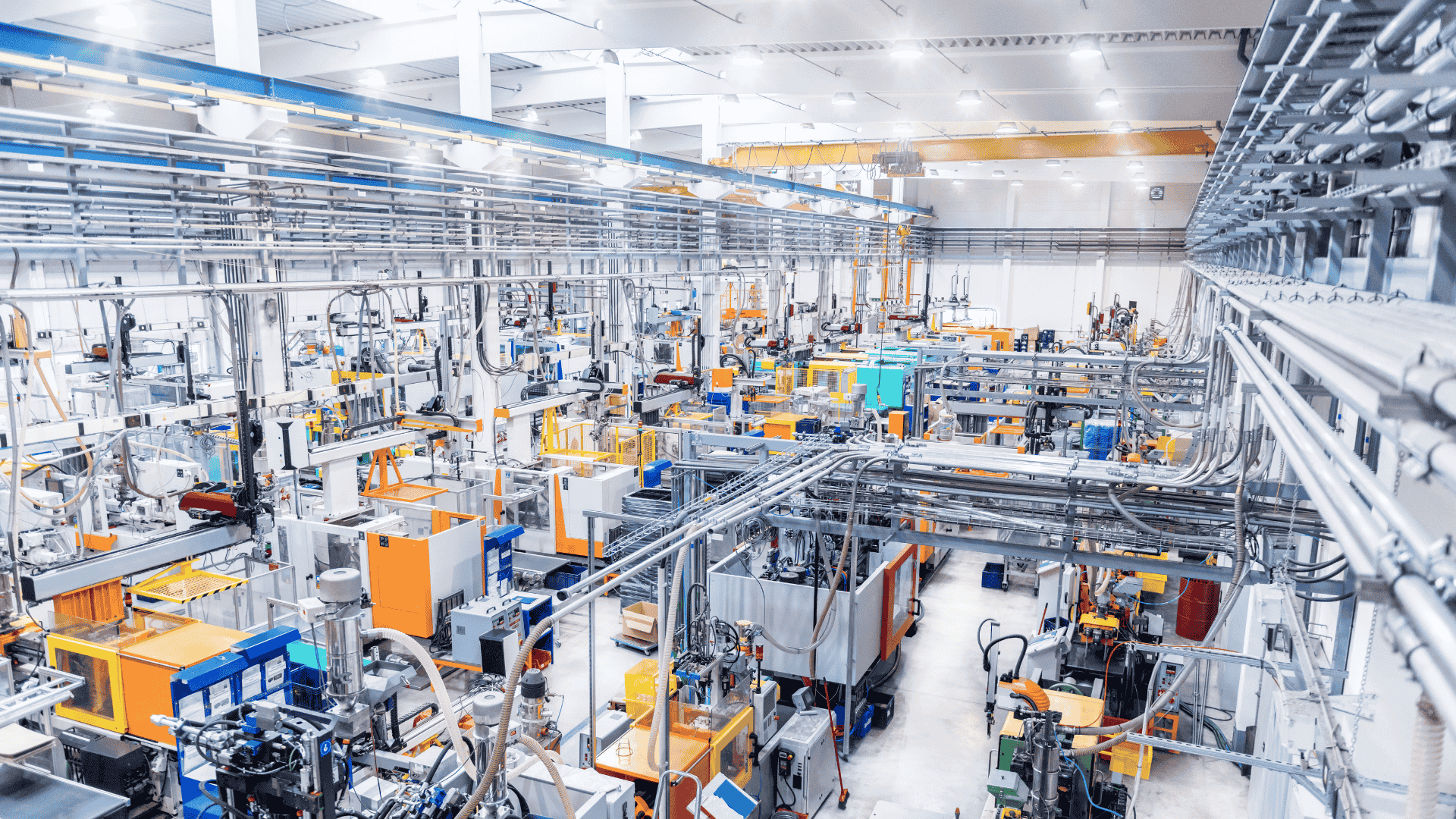

A smart factory is a manufacturing environment built on autonomous processes, continuous optimization, and machine-driven decision logic. It operates through connected systems that collect, transfer, and process machine data without manual intervention. The objective is the systematic removal of inefficiencies across production, logistics, equipment performance, and resource allocation. The concept aligns with Industry 4.0 and Industry 5.0, where digital integration replaces isolated manual workflows.

According to the definition widely used in industrial research, a smart factory relies on sensor networks, cyber-physical systems, machine learning, and standardized data communication frameworks. IBM provides an overview of smart factory characteristics here.

NIST outlines foundational principles of smart manufacturing and data interoperability here.

The smart factory uses machine-to-machine communication to execute tasks without human direction. Production stages interact through unified data channels. Machines interpret conditions, adjust parameters, and correct process deviations in real time. This creates a predictable and stable production environment with reduced error rates and minimal resource waste.

Structural Components of a Smart Factory

A smart factory uses a layered structure. Each layer performs a defined role in the flow from physical hardware to decision automation.

-

Physical Layer

Sensors, actuators, robots, conveyors, and industrial machinery generate continuous streams of operational data. Temperature, vibration, speed, torque, pressure, and energy consumption form the primary measurement signals. -

Connectivity Layer

Machines transmit data through Wi-Fi, Ethernet, 5G, MQTT, OPC UA, Modbus TCP, or other industrial communication standards. This removes manual data collection and eliminates delays associated with human reporting. -

Data Layer

Collected signals enter a centralized database, data lake, or cloud platform. Filtering, normalization, and preprocessing remove noise and convert raw data into structured machine information. -

Intelligence Layer

AI models evaluate the data. Machine learning algorithms detect anomalies, identify patterns, forecast failure timelines, calculate quality deviations, and determine optimal machine parameters. -

Execution Layer

The system performs automated decisions. It adjusts machine behavior, schedules maintenance tasks, orders spare parts, modifies production sequences, or allocates resources.

This architecture supports self-regulating industrial environments.

Operational Advantages of a Smart Factory

A smart factory produces gains across productivity, quality, traceability, and utilization. The benefits compound as more assets become connected and integrated.

1. Production Efficiency

The smart factory identifies unused capacity, cycle losses, energy waste, and hidden bottlenecks. AI models calculate optimal setpoints, reduce changeover losses, and raise throughput. Continuous data streams eliminate reliance on subjective operator judgments.

2. Quality Improvement

Real-time measurement of test parameters enables immediate reaction to deviations. Automated analytics highlight drift, tool wear, thermal instability, contamination patterns, and assembly inconsistencies. Quality control no longer relies on periodic manual inspection. The system enforces accuracy throughout the full production cycle.

3. Traceability

Every material movement, machine state, cycle event, and product stage becomes accessible. Traceability resolves responsibility, identifies defective batches instantly, and reduces recall costs. Smart factories provide pre-production prevention, in-production surveillance, and post-production evaluation as a unified chain.

4. Lean Production

The smart factory removes redundant steps, manual reporting tasks, and slow information paths. Automatic data collection supports lean objectives by giving immediate insight into waste categories, downtime origins, and flow interruptions.

5. Production Transparency

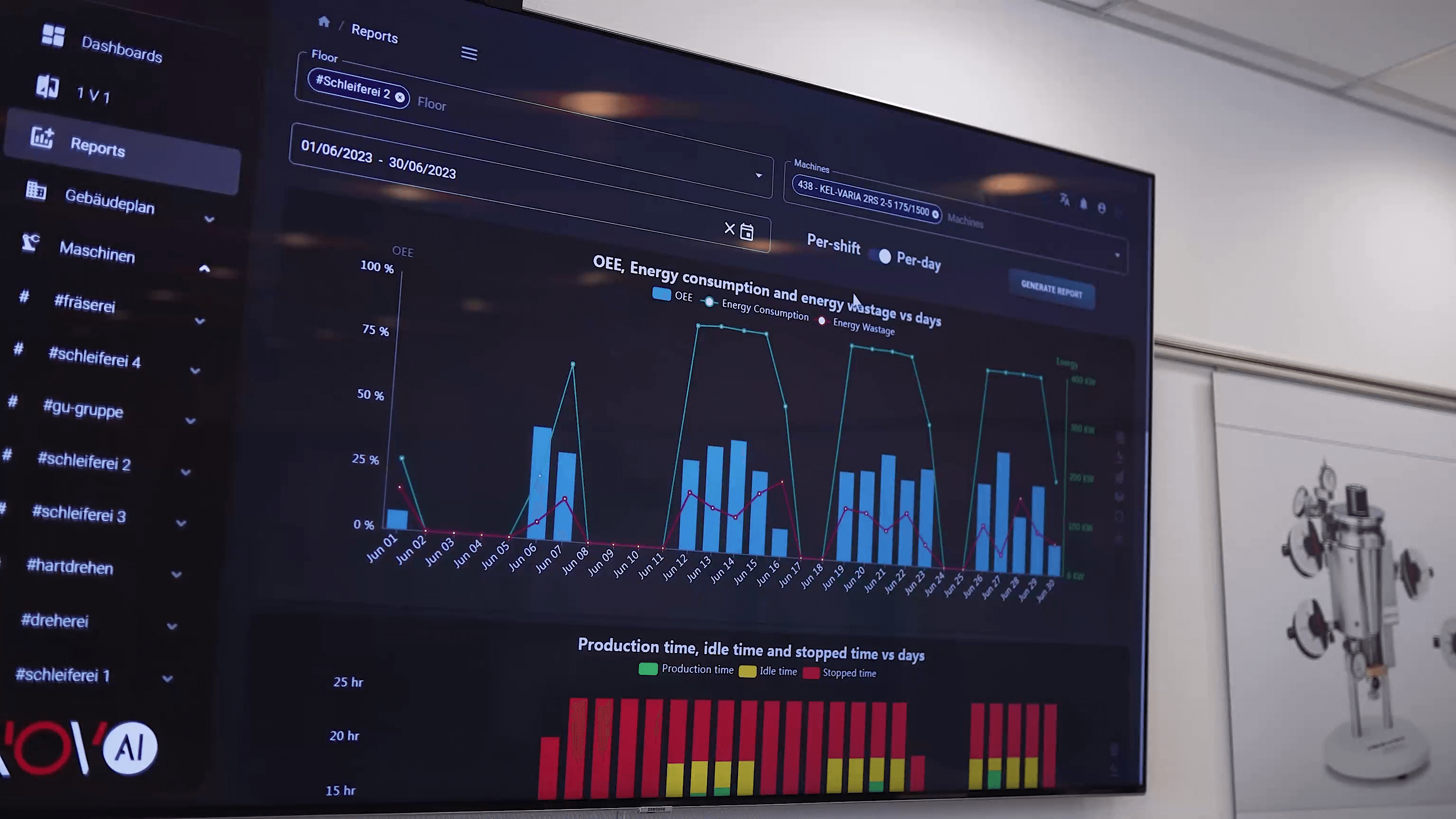

The system eliminates black-box environments. Managers access real-time dashboards showing machine utilization, throughput, scrap, operating conditions, and maintenance needs. No manual aggregation is required. Transparency supports faster decisions and greater accuracy in planning, costing, and forecasting.

6. Execution Strength

Standardized processes, automated workflows, and unified protocols increase the stability of operations. Human error decreases. Machine networks respond instantly to new conditions. Production environments gain reliability and repeatability.

Technology Groups Driving Smart Factory Adoption

A smart factory is not defined by a single tool. It is a combination of technologies working together.

Industrial IoT

Sensors capture temperature, vibration, acoustics, energy data, optical parameters, torque, and pressure. Equipment health becomes measurable.

Edge Computing

Critical calculations, anomaly detection, and latency-sensitive processing occur at the machine site. This reduces delays and improves responsiveness.

Cloud Systems

Scalable data storage and centralized analytics unify information across production lines, plants, or regions.

AI and Machine Learning

Models evaluate historical and real-time data. They identify failure patterns, adjust workflows, schedule maintenance windows, and forecast demand.

Cyber-Physical Systems

Physical equipment and digital intelligence operate as a single integrated system.

Robotics and Automation

Material handling, assembly, inspection, and packaging tasks execute autonomously. Robots communicate with machines to synchronize movements.

These technologies combine to create the continuous optimization cycle that defines a smart factory.

Impact on Workforce and Organizational Structure

Smart factories shift human responsibilities. Workers transition from manual execution to supervision and technical oversight. Operators monitor machine recommendations. Engineers validate AI outputs and handle system exceptions. Maintenance teams receive predictive alerts instead of reacting to unexpected failures.

The introduction of smart factory workflows requires new competencies:

-

analysis of machine data

-

understanding of automated decision chains

-

ability to interpret AI-generated insights

-

handling of digital tools, interfaces, and dashboards

-

structured troubleshooting supported by diagnostic algorithms

The organizational culture becomes data-centric. Decision authority aligns with measurable information instead of intuition.

Scalability and System Expansion

Smart factory infrastructure expands without disrupting core operations. Adding new machines, sensors, or analytics modules requires minimal integration effort. Unified communication standards ensure compatibility.

Scalability includes:

-

connecting additional production lines

-

integrating new machines

-

deploying cross-site cloud analytics

-

unifying maintenance workflows across multiple plants

-

updating AI models to reflect new products or process conditions

The modular structure protects long-term investments.

Transition Toward Industry 5.0

The smart factory provides the foundation for Industry 5.0. Autonomous decision-making continues to expand. Systems combine logical reasoning, process knowledge, and machine learning to anticipate requirements in advance. Human workers cooperate with intelligent machines. Production flexibility increases. Customized products become standard.

The long-term trajectory includes:

-

autonomous equipment fleets

-

complete supply chain synchronization

-

self-healing production lines

-

reduction of manual interventions

-

micro-factories capable of localized production

-

integration of sustainability analytics

Machines will access information networks, allocate resources, and optimize output at scale.

Conclusion

The smart factory delivers a structural shift in manufacturing. Data replaces guesswork. Automation replaces manual intervention. Optimization replaces static planning. Companies gain higher output, stronger reliability, better quality, improved traceability, and reduced waste.

The transformation requires system integration, digital infrastructure, and organizational alignment. The result is a production environment capable of continuous improvement and autonomous operation.