Unconnected Machines: How 2–4 hours of Downtime per Shift will Destroy your Margin

What does 2–4 hours of stoppage per shift really cost your shop floor? If your plant still runs with unconnected machines, the answer is: far more than you think. Every minute without real-time visibility multiplies lost throughput, late deliveries and hidden labour costs across shifts and months. This piece lays out the math, shows practical examples, and gives production managers a clear 60–90 day plan to stop the leak.

The Real Impact 1: Hidden Cost: Unconnected Machines

When a machine goes down for two to four hours in a single shift, it is not just lost cycle time. You lose upstream and downstream value, extra setup and teardown, expedited shipping costs and operator idle time. Siemens' The True Cost of Downtime (2024) estimates unscheduled downtime can sap up to 11% of annual revenues for affected lines, a figure that hits SMEs especially hard where profit per part is often single-digit percent (Siemens, 2024).

Translate that percentage into real numbers for a typical German Mittelstand shop producing €50M per year: 11% equals €5.5M lost potential revenue; even halving that impact through improved monitoring yields a multi‑million euro difference. Many SMEs undercount indirect costs: overtime to catch up, inventory buffering, quality rework and customer penalties. These add up quickly and often sit off the radar of monthly P&L reviews.

Recent industry overviews put per‑hour downtime costs at very high levels. Reports cite figures ranging from tens of thousands to more than $100,000 per hour for complex industrial operations; some extreme ABB examples reach up to $260,000 per hour in specific sectors (Industry EMEA, 2025).

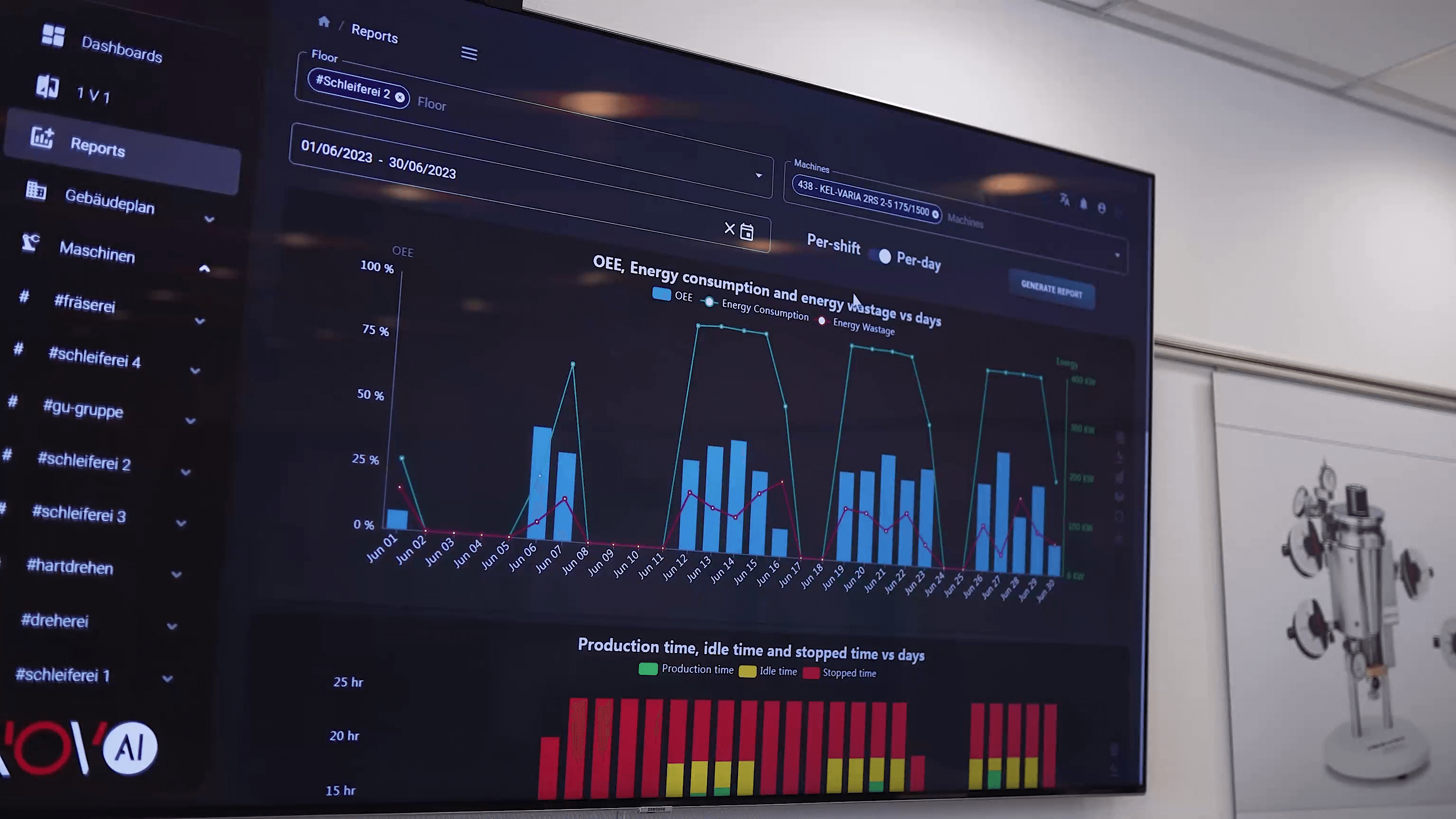

The Real Impact 2: Lost OEE and Productivity

Overall Equipment Effectiveness (OEE) captures the combined effect of availability, performance and quality. Losing 2–4 hours in an 8‑hour shift cuts availability dramatically: four hours lost across three shifts reduces daily availability by roughly 17%. For a line running at 30% OEE, this sort of loss can push usable capacity below viable levels. In many cases, these losses stem from unconnected machines that operate without real-time visibility into states and interruptions. By contrast, many retrofit projects report OEE lifts from around 30% to 55–60% after targeted monitoring and process changes.

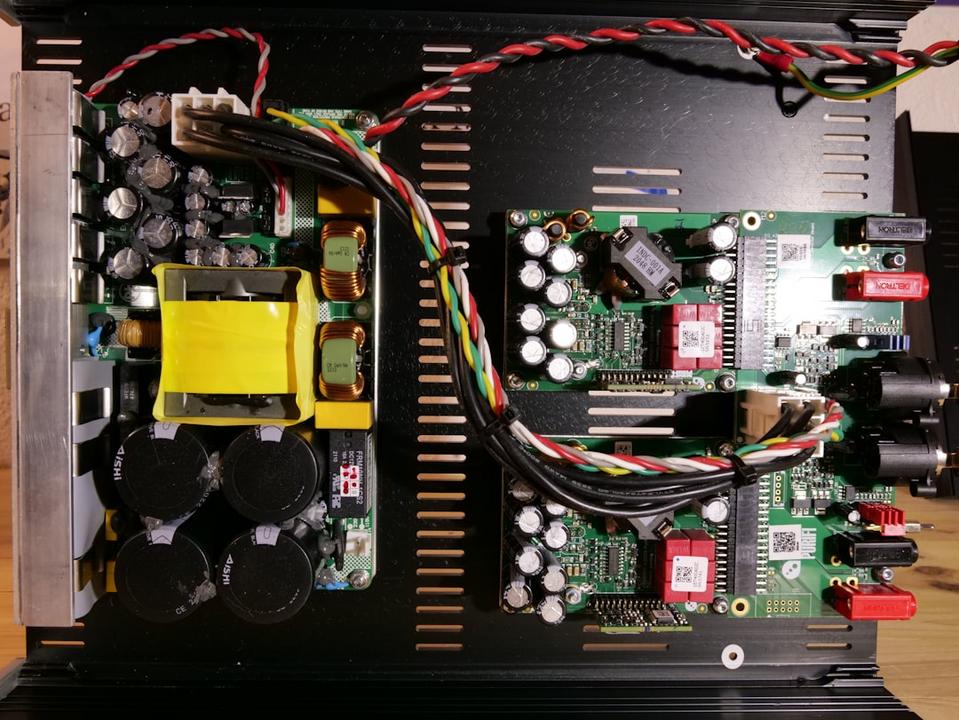

Modern solutions like Novo AI's WatchMen platform with its AVA Sensor Module offer machine‑agnostic retrofitting that reads electrical, vibration and state signals to detect stoppages within seconds. Local edge analytics shrink fault‑to‑fix time: what used to be hours of blind downtime becomes minutes of targeted action. That time conversion is how OEE moves from a theoretical metric to immediate cash flow improvement.

The Real Impact 3: Energy Waste and Quality Drift

Unconnected machines are blind to energy inefficiencies. Idle motors, heaters and compressors continue to draw power during unexpected stops. Tracking energy per part and per cycle can reveal 5–15% waste in poorly instrumented lines. Correlating stoppage events with energy spikes can also expose failing bearings or misaligned drives before they cause scrap.

Energy tracking is often low‑hanging fruit: savings can pay back sensor and analytics investments within months for energy‑intensive processes such as heat treatment, injection moulding or large compression systems. For many facilities, these energy savings compound the revenue protection benefits from reduced stoppages.

The Real Impact 4: Supply Chain and Delivery Risk

Two hours of stoppage often becomes a delivery problem. If a critical component is delayed, the downstream line waits, shipments are pushed, and customers face missed windows. Buffering with safety stock is a common reaction, but it increases working capital and hides systemic issues. The smarter approach is to reduce uncertainty through real‑time visibility, thereby lowering both stock and risk.

How to Calculate the Cost

Making the cost tangible changes the conversation in management meetings. Use a simple formula: Cost_per_shift = (Revenue_per_shift * Fraction_lost) + Direct_costs. Example: a line generating €25,000 per shift, running eight hours, loses three hours: throughput loss = €9,375. Add overtime (€1,200), expedited freight (€800) and scrap (€500) and the one‑shift hit exceeds €11,875. If this repeats 250 days per year, the annual cost approaches €2.97M.

This calculation is illustrative but useful: small daily losses compound into significant sums. Reducing stoppage minutes by 30% in this example saves roughly €900 per shift or over €200k per year — a credible business case for targeted retrofits and analytics.

2. Practical Example: Unconnected Machines at Work

Consider a family‑owned metal parts manufacturer in Bavaria with six CNCs. Before instrumentation they reported frequent 2–3 hour downtimes caused by tool wear, chatter and spindle failures. After retrofitting simple sensor modules and running local analytics they cut average stoppage time by 50% and lifted OEE on the critical line from 35% to 55% in year one. That translated to regained capacity, lower overtime and a clear cut in expedited shipments to key customers.

Similar vendor case studies and academic reviews highlight the pattern: quick sensor pilots reveal recurring root causes that can be fixed without full machine replacement. ScienceDirect’s Industry 4.0 research highlights preventative maintenance optimisation as a high‑value application of connected technologies (ScienceDirect, 2024).

3. Counterintuitive Costs

Hidden costs are behavioural. When short stops are normal, teams stop treating them as exceptions. Maintenance becomes reactive, operators accept lower throughput, and planners add padding. These cultural costs compound technical problems: what starts as a few minutes of hiccups can escalate into full‑shift halts if root causes remain invisible.

Authoritative reports underline the scale: Siemens and other analyses estimate cumulative global costs of unplanned downtime in the hundreds of billions annually. For Mittelstand firms, preventing one repeated daily stoppage can fund further digital investments and change plant culture toward continuous improvement.

3 Ways to Reduce Downtime

Here are concrete steps production managers can test in the next 60–90 days:

- Run a pilot: retrofit 2–4 critical machines with non‑invasive sensors and measure baseline downtime for 30 days.

- Enable real‑time alerts: define a tight alert chain—fault detected, operator action, maintenance ticket—so issues are resolved within minutes, not hours.

- Use historical analytics: group events by root cause (tooling, set‑up, operator, part variation) and run weekly action reviews to eliminate recurring failures.

Practical ROI: a €20k pilot (sensors, install, analytics) that reduces stoppages by 20% and frees one hour per shift can yield €50k–€150k annual value depending on throughput. These payback figures align with retrofit vendor claims and make pilots low‑risk experiments for plant managers.

Additional Guidance

When evaluating vendors, prioritise machine‑agnostic retrofits and on‑prem processing—this reduces integration time and avoids cloud‑only lock‑in which many SMEs distrust. This is especially relevant in environments with unconnected machines, where legacy equipment lacks built-in data interfaces. Security, data sovereignty and clear data‑ownership terms often determine approvals in German firms. Modern solutions that pair simple sensors with edge AI and operator dashboards unlock practical wins quickly.

For example, an AVA Sensor retrofit combined with WatchMen analytics can surface recurring spindle issues and enable predictive maintenance scheduling around planned downtime, avoiding costly surprise shifts.

Security and Data

Data protection matters. Edge analytics that keep raw sensor streams on‑premises while exposing aggregated KPIs to a secure portal are preferred. Demand encryption, role‑based access and contractual clarity on data ownership. Novo AI emphasises secure local processing and modular retrofits that align with these expectations, easing approvals with works councils and IT teams.

The Bottom Line

Two to four hours of stoppage per shift is a persistent margin eroder. The cost appears as lost parts, overtime, expedited freight, energy waste and damaged customer trust. A disciplined approach—pilot sensors, real‑time alerts, and weekly analytics reviews—turns unconnected machines into predictable assets. Modern retrofit solutions like WatchMen provide a feasible path for SMEs to capture these gains without full‑line replacement.

Start with one line, measure rigorously and reinvest gains. Small visibility investments compound into sustainable margin protection and align with broader Industry 4.0 goals for efficiency and sustainability. Start small, show the savings, and scale across the plant within six to twelve months to sustain margin improvements.

References

- Siemens – The True Cost of Downtime (2024) - Industry survey and analysis (accessed: 2026-02-17)

- Industry EMEA – The Cost of Unplanned Downtime (2025) - Market overview and hourly cost estimates (accessed: 2026-02-17)

- ScienceDirect – Integrating Industry 4.0 for Sustainability (2024) - Academic perspectives on Industry 4.0 impacts (accessed: 2026-02-17)

- Novo AI – WatchMen solution page - Product overview and case studies (accessed: 2026-02-17)

- ISM – Unscheduled Downtime Analysis (2024) - Commentary on downtime metrics (accessed: 2026-02-17)