Despite the obvious benefits of technology in terms of the pace and quality of production, machine breakdowns are proving to be a massive hurdle for countless businesses. One of the leading challenges of running a smooth and efficient production line is the random faults in machinery.

Thanks to digital transformation, however, it is now possible to monitor your machinery and stay on top of any errors in the system without handicapping your human resources. Let’s explore this in detail below.

What is Machine Data Acquisition (MDA)

The machine data acquisition process is spearheading the digital revolution in production lines all around the globe. It’s a process using which managers can bridge the gap between production planning and the ground realities of production lines.

In more specific words, machine data acquisition relates to how you gather data from your machines, the protocol you use to standardize that data, and then how you process that data into meaningful insights for your organization’s production efficiency.

The collected data could be about the machinery or the production output itself, but the end goal remains the same. Managers get a data-backed look into their production processes, discover gaps and opportunities for optimization, and then realize productivity gains by continually improving the production processes using data analysis.

Now, some organizations choose to monitor their machine data manually by having someone on their team record everything in an excel sheet by hand. Needless to say, that’s a cumbersome and resource-intensive process that’s prone to an unacceptable margin of error.

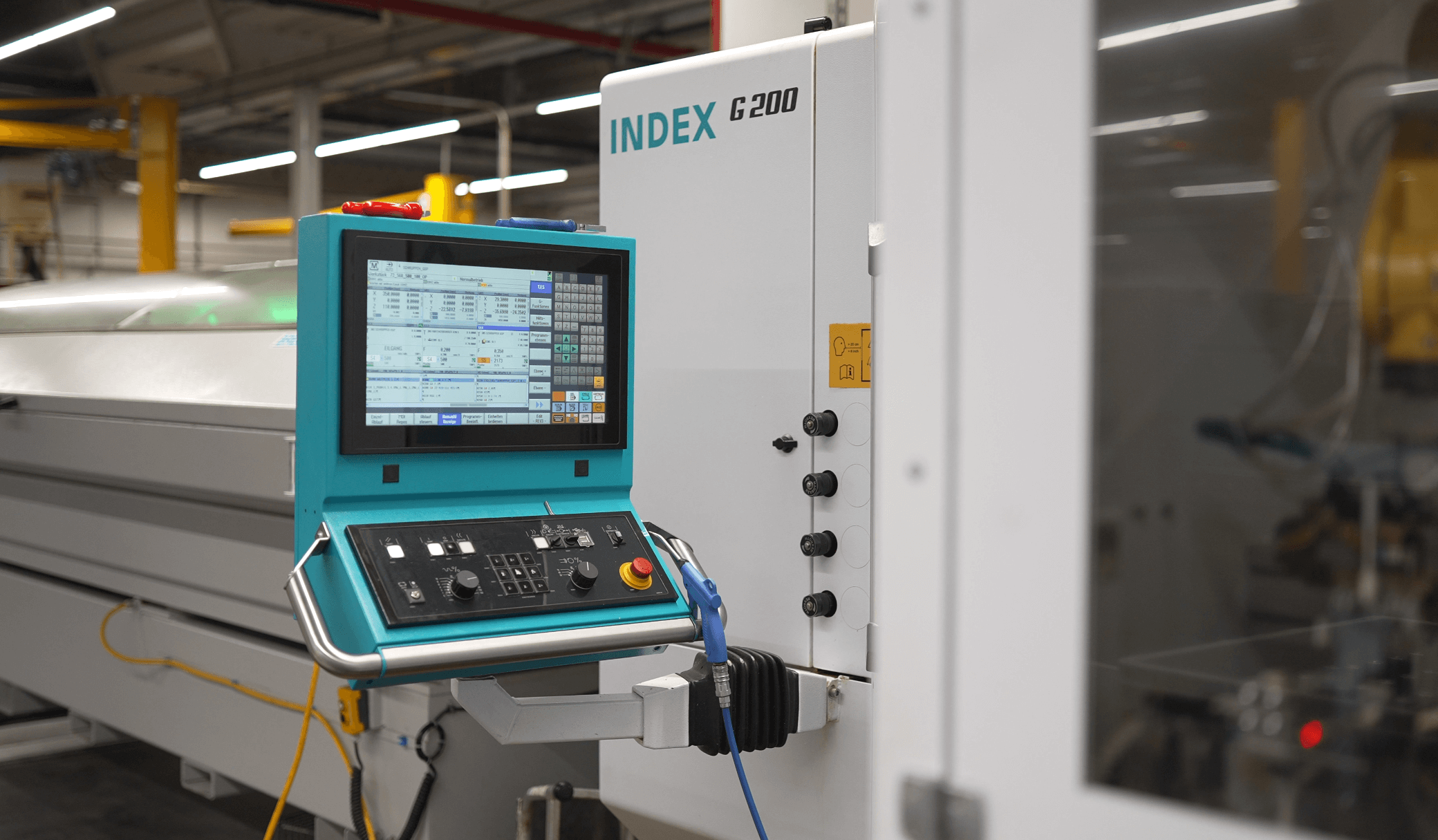

Thanks to the digital revolution of the 21st century, you can use a digital system like FORCAM FORCE Bridge to gather data automatically from your machines by leveraging common communication standards found on most machines.

An automated system runs in the background and gathers excellent-quality data without the need for any daily tinkering or manual input from someone on your team. The system then unifies the data for effortless analysis by management, making practical insights and productivity gains far more feasible.

Needless to say, automatic machine data acquisition is the way to go in the 21st century.

Image by aleksandarlittlewolf on Freepik