Maintaining machines in production is a must. Besides the question of how to do maintenance the best way possible stands, one other important question: When to do maintenance and when to cause interruption of production. In this post, we will dive into the importance of maintenance in production and explore the differences between predictive and preventive maintenance.

Preventative Maintenance

Manufacturers traditionally provide recommended maintenance timelines or repair things only if they break. This approach results in the timing of maintenance arising from the experience of the manufacturers. Preventative Maintenance calls for regularly scheduled and time-based maintenance to take action before things break Reactive Maintenance is fixing things only after they have already broken down.

Even though those ways of maintenance are the most common, they still involve some problems. Performing preventative maintenance requires lots of planning, record keeping, and scheduling, and it is possible to do the maintenance too often as the risk of failure could be fatal if not done enough. This leads to more downtime than is really necessary. For Reactive Maintenance unexpected interruptions caused by production failure can also lead to unnecessary downtime.

Traditional means of maintenance, lack perfect timing. If done too late, things might get worse and unplanned downtime arises. If done too often, losses in production result in unnecessary maintenance stops.

Predictive Maintenance

This is where Predictive Maintenance comes in handy. Performing it is required only when it is necessary.

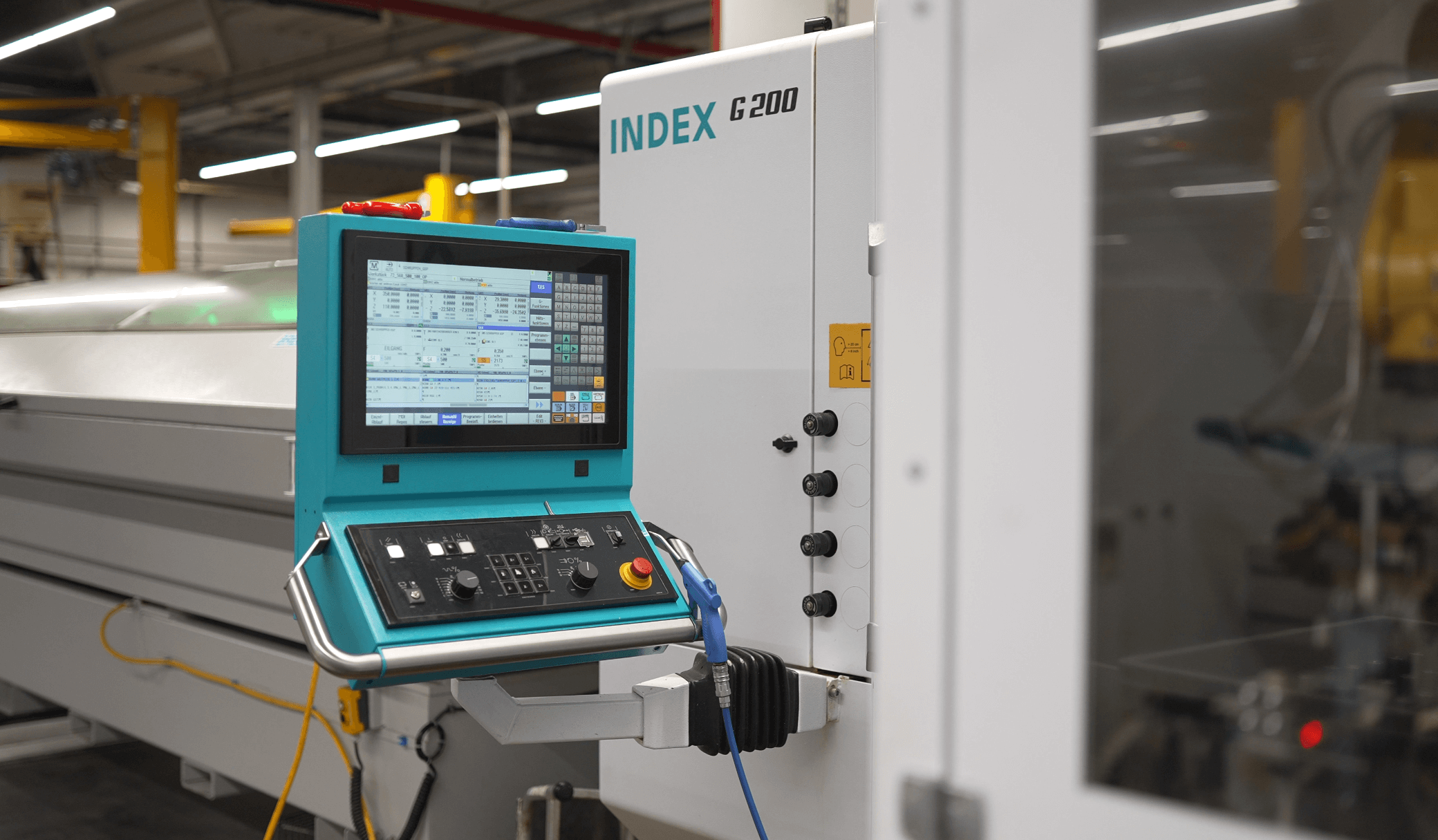

But how is this done? Sensors gather information about the manufacturing process in real-time to track conditions. By monitoring the status of production based on the gathered information, you can determine when maintenance will be necessary. By monitoring the information, you can keep track of the production’s status, and determine the necessary time for maintenance. This enables you to perform maintenance only when required, avoiding maintenance done too often or too late.

NOVO AI can help you predict the right time for maintenance. If you are interested, feel free to .

Image by Freepik.