What Is Data?

According to the oxford dictionary, Data are raw facts and statistics collected together for reference or analysis.

In every company, various departments produce certain data. It plays an important role in the production and operation of a company. It comes in raw form, so pre-processing is necessary. Pre-processing is a process of cleaning and converting information into a form that is valuable and useful.

The picture shows how data is acquired, cleaned, and deployed.

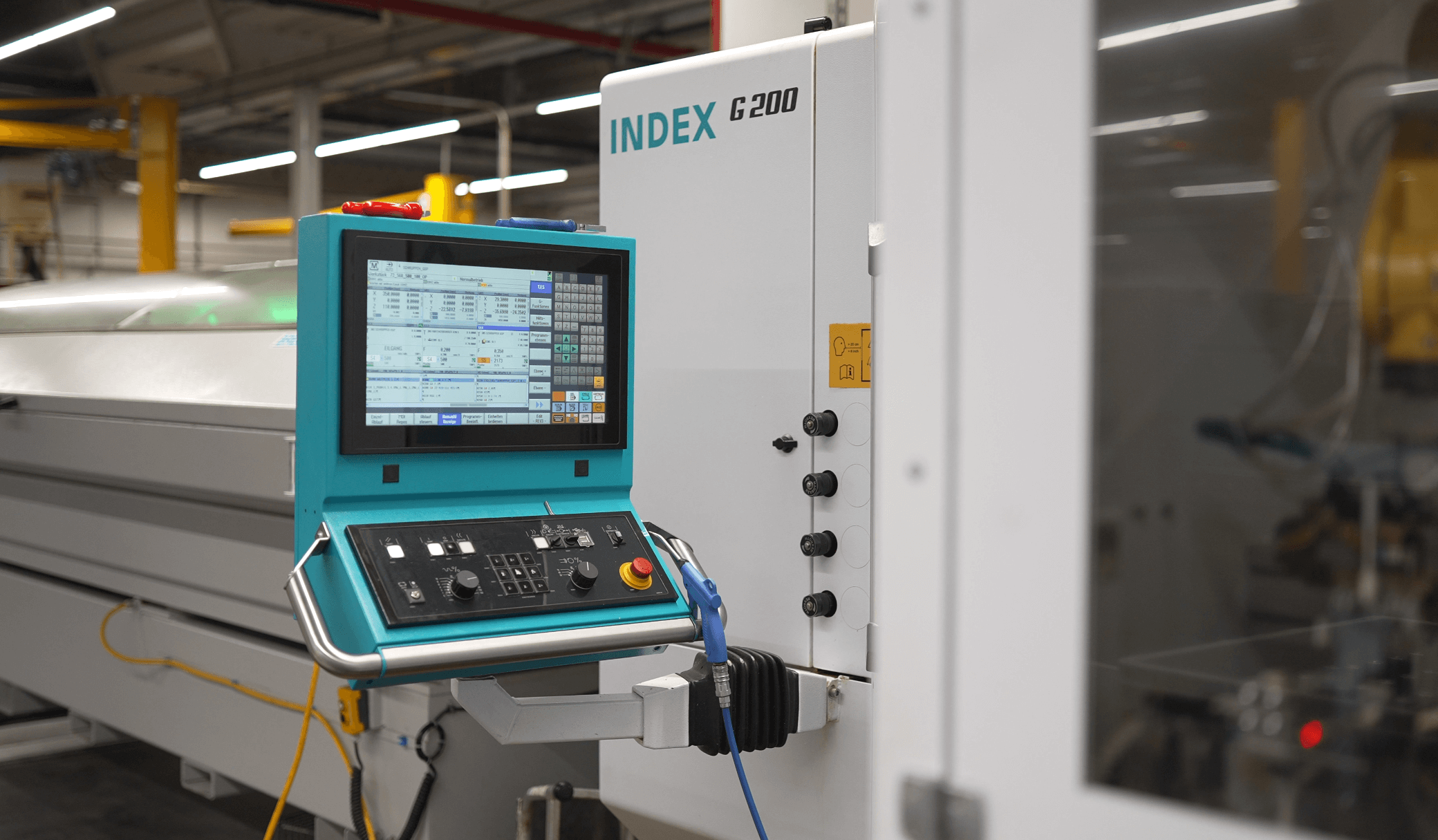

Understanding your machine and the kind of data you have can help determine what pre-processing methods to use. For example, if you are filtering noisy vibration information, knowing the frequency range can help you choose pre-processing techniques. Data has become indispensable information that almost all business activities rely on for production, operation, strategy, and so on.

Top Three Importance of Data

Predictive Maintenance

The most important part of using data is the cleaning/processing and augmentation process. Without this process, Predictive analysis or maintenance cannot be carried out. The goal of predictive maintenance is to extend the useful life of the equipment and prevent failures. Unplanned equipment downtime is extremely disruptive to any business. It is very important to keep field equipment running to:

1. maximize utilization,

2. minimize costly unplanned downtime,

3. reduce the risks of abnormal operations, safety risks, and environmental risks.

Anomaly diagnosis is a common method, it can identify unexpected behavior of the device. Anomaly detection solutions are usually more accurate than simple rule-based failure detection methods. This solution is very helpful in preventing costly failures and service interruptions.

For example, Southwest Airlines actually send data to the National Weather Service, augmenting the government agency’s weather balloons with more frequent and precise information on current conditions like humidity and the potential for icing or turbulence. More accurate forecasts mean better scheduling and fewer flight disruptions. Delays are responsible for $8 billion in losses for the airline industry, according to Bloomberg. “You can’t take credit for the event that you avoid,” says Tim Leonard, Southwest Airlines director of flight ops compliance and operations. Therefore, he says the predictive analysis also has secondary benefits, like avoiding the public-relations disasters of delays or engine failures. “All those tools help you prevent it because they make the pilots and the mechanics and the employees more aware,” Leonard tells Business Insider

Cost Savings

Big data can help change the way manufacturing and production processes are carried out. The information produced can help reduce the cost of production and packaging during manufacturing. Additionally, companies that implement analytics can also reduce the cost of transport, packaging, and warehousing, which can in turn help cut inventory costs for massive savings. Manufacturing companies are reaping huge benefits by deploying Big Data technologies.

For instance, Automakers worldwide use data analytics to monitor the cost of steel and other raw materials, helping them identify when they can purchase at the best price point. How can this be done? A database of several suppliers is built on a Hadoop framework; these tracks which supplier offers the most competitive price and can deliver at the optimal time. This can cause Car manufacturing costs to reduce significantly. With the deployment of Big Data analytics in the digital space, companies are better able to understand their customers. This enables them to plumb the depths of customers’ paths to purchase and online behaviors. In turn, retailers have been able to create targeted incentives and offers, which equals stronger brand loyalty and more sales.

Companies operating in any industry can gain from using Big Data and IoT technology. By identifying resource and capital drains, they can gain incremental benefits and revenue over a period of time. By developing better customer relationships, they gain higher sales and eventually more revenue.

Decision-making process

Correct analysis can help companies make informed business decisions. Allowing corporate managers to greatly increase decision-making efficiency and improve decision-making quality, largely affected the operation and performance of a company. The importance of data in decision lies in consistency and continual growth. Data enables companies to create new business opportunities, generate more revenue, predict future trends, optimize current operational efforts, and produce actionable insights. The digital world is in a constant state of flux, and to move with the ever-changing landscape around you, you must leverage data to make more informed and powerful business decisions. Data-driven business decisions make or break companies.

MIT Sloan School of Management professors Andrew McAfee and Erik Brynjolfsson once explained in a Wall Street Journal article that they performed a study in conjunction with the MIT Centre for Digital Business. In this study, they discovered that among the companies surveyed, the ones that were primarily data-driven benefited from 4% higher productivity as well as 6% higher profits. Companies that approach decision-making collaboratively tend to treat information as a real asset more than companies with other, more ambiguous approaches.

SUMMARY

Recent research from LNS Research and MESA International found that better forecasts of product demand and production (46%), understanding plant performance across multiple metrics (45%), and providing service and support to customers faster (39%) are the top three areas where data analytics software can improve manufacturing performance. However, manufacturing organizations have been slow to adopt the technology. Figures suggest that less than 20% of manufacturers have implemented a big data analytics solution. In recent research from Industry Week, two-thirds of manufacturing executives surveyed felt they were not maximizing the potential benefits of big data analytics tools for operational insight and decision-making.

For more information, reach out to us.