Realtime Machine Monitoring: Eliminating Downtime Through Visibility and Maintenance

Unplanned downtime remains one of the most disruptive and costly problems in industrial operations. When machines unexpectedly stop due to equipment failures, software malfunctions, mechanical wear, or human error, production processes are forced to halt without warning. These interruptions result in lost output, delayed delivery schedules, excessive repair costs, and significant resource inefficiencies. Realtime machine monitoring has emerged as one of the most effective solutions for reducing these losses by enabling continuous visibility into machine performance and early detection of abnormalities.

Deloitte estimated in 2017 that manufacturing facilities can lose between 5% and 20% of their overall productivity due to unplanned downtime. Emerson reported that 42% of unplanned downtime originates from equipment failure. These numbers reveal how deeply downtime affects production lines and how essential it is for companies to modernize their maintenance strategies. Realtime machine monitoring provides organizations with the ability to track asset conditions as they happen, analyze operational data continuously, and respond to anomalies before failures unfold.

As digital transformation accelerates across industries, realtime machine monitoring has become a core building block of modern industrial operations. By connecting machines to sensors, analytics platforms, and cloud infrastructure, organizations gain unprecedented transparency into machine behavior, health status, and performance trends. This shift enables maintenance teams to move away from reactive interventions and toward proactive, predictive, and optimized maintenance workflows.

Why Realtime Machine Monitoring Matters

Realtime machine monitoring addresses a fundamental challenge in manufacturing: the inability to detect early signs of failure. Most machine failures develop gradually rather than suddenly. Vibration levels change, temperatures rise, energy consumption increases, mechanical components show irregular friction, and acoustic signatures shift subtly. Without continuous monitoring, these early-stage signals remain invisible.

Realtime monitoring systems track these signals and detect abnormal patterns in real time. This capability allows businesses to:

-

Identify failure risks earlier

-

Reduce emergency repairs

-

Minimize unexpected downtime

-

Improve worker safety

-

Extend equipment lifespan

-

Optimize energy consumption

-

Increase throughput and operational stability

Studies from the National Institute of Standards and Technology (NIST) highlight the importance of accurate and timely data in manufacturing quality and reliability monitoring. More information is available at NIST.

With realtime machine monitoring in place, factories gain a reliable data stream that reflects the true condition of their equipment, enabling precise and timely decision-making.

Preventing Downtime with IoT Sensors and Predictive Analytics

Achieving reduced downtime depends on deploying the right combination of technologies and processes. The primary goal of realtime machine monitoring is to detect anomalies early and provide actionable information long before a component reaches a failure point. Predictive maintenance, supported by realtime monitoring, fulfills this requirement by analyzing machine data continuously and forecasting potential issues.

IoT Sensors: The Foundation of Realtime Monitoring

IoT sensors are installed on machines to monitor a range of parameters, including:

-

Vibration signatures

-

Acoustic emissions

-

Temperature variations

-

Pressure levels

-

Torque and rotation speed

-

Energy consumption

-

Motor currents

These sensors operate continuously and transmit data without requiring human intervention. Because they provide realtime measurements, even slight deviations from normal machine behavior can be detected immediately.

Data Transmission and Cloud Connectivity

Sensor data is sent to cloud-based IoT platforms through secure Wi-Fi, Ethernet, or industrial communication protocols. Cloud platforms enable:

-

Scalable data storage

-

High-speed processing

-

Distributed access across teams

-

Integration with MES, ERP, and CMMS systems

-

Historical trend visualization

By moving data into the cloud, companies eliminate the limits of on-premise data storage and ensure that machine insights remain accessible across departments.

Predictive Analytics and Automated Alerts

Data from realtime machine monitoring systems is fed into analytics engines capable of identifying correlations, anomalies, and predictive patterns. Machine learning models evaluate historical and realtime data simultaneously to assess the risk of future failures.

When a risk threshold is exceeded, the system automatically sends alerts to technicians. Maintenance teams receive notifications early enough to schedule service without interrupting ongoing operations.

This transformation—from unexpected breakdowns to planned interventions—is what makes realtime machine monitoring so valuable. It turns maintenance from a reactive cost center into a proactive performance driver.

Operational Benefits of Realtime Machine Monitoring

Realtime machine monitoring delivers improvements across all layers of production. These benefits impact operational efficiency, cost structure, worker safety, and sustainability.

1. Reduction of Downtime Events

Continuous data access means teams can detect irregularities before they escalate. Downtime becomes predictable rather than chaotic.

2. Improved Maintenance Planning

With realtime insight into machine health, maintenance teams shift from reactive repairs to strategic, well-planned interventions.

3. Enhanced Process Quality

Realtime data reveals trends that help optimize production parameters, detect quality deviations, and reduce scrap rates.

4. Increased Equipment Lifespan

By preventing machines from operating under harmful conditions, wear and tear decrease significantly.

5. Lower Operational Costs

McKinsey reports that data-driven maintenance strategies can reduce costs by 10% to 40% across industries:

https://www.mckinsey.com

6. Better Workforce Allocation

Technicians focus on real problems rather than routine inspections, improving productivity and morale.

Technical Requirements for Realtime Machine Monitoring

To successfully implement realtime machine monitoring, companies need the right combination of hardware, software, and organizational readiness.

A. Sensor Infrastructure

Sensors must match the physical characteristics of the machine and capture relevant indicators at sufficient sampling rates.

B. Networking and IT Infrastructure

Stable connectivity, secure data channels, and robust network configuration are essential for continuous data transmission.

C. Data Analytics Platform

The processing layer must support:

-

High-frequency data ingestion

-

Pattern recognition

-

Predictive analytics

-

Visualization dashboards

D. Trained Personnel

Operators and technicians must understand:

-

How to interpret dashboard indicators

-

How to respond to alerts

-

How to integrate insights into workflows

Training is often the most underestimated requirement for effective realtime monitoring.

Realtime Machine Monitoring with NOVO AI

NOVO AI provides a comprehensive approach to realtime machine monitoring through its IIoT sensor AVa and the Watchmen analytics platform.

AVa IIoT Sensor: High-Resolution Machine Monitoring

AVa gathers vibration, acoustic, and other operational data directly from machines. It detects subtle anomalies in critical machine components and forecasts maintenance needs. AVa transfers data to the cloud using secure Wi-Fi connectivity, ensuring continuous visibility without disrupting the machine.

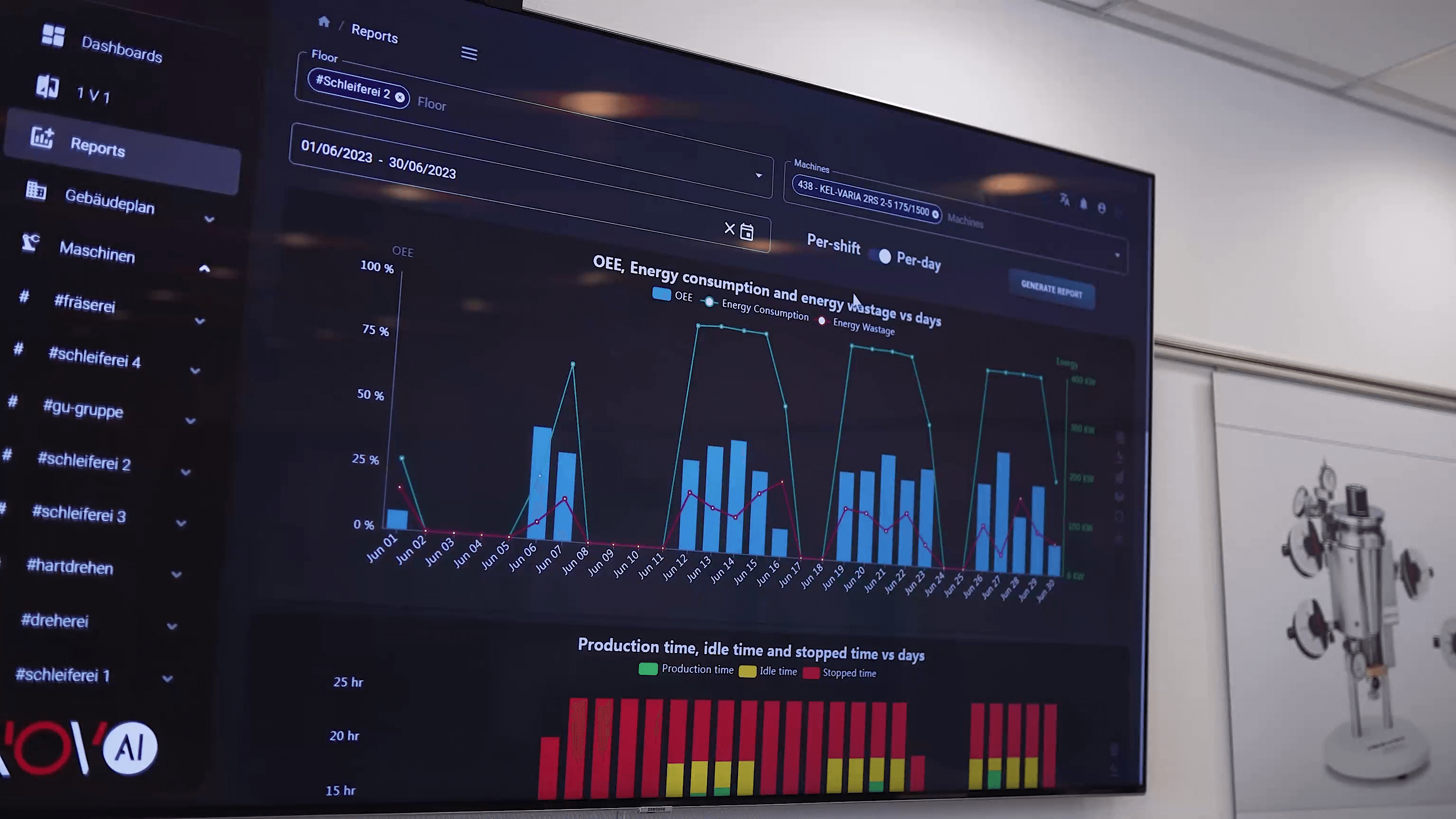

Watchmen Platform: Cloud-Based Analytics and Realtime Dashboards

Once the AVa sensor transmits data to the cloud, the Watchmen platform processes and analyzes the incoming information. The system applies intelligent data models to identify irregular patterns, classify machine states, and present insights clearly on the Watchmen Dashboard. This dashboard places users at the center of their production process by giving them:

-

A realtime overview of machine status

-

Access to historical performance data

-

Condition-based alerts

-

Trend analysis for maintenance planning

-

Clear visualizations of anomalies and risks

Realtime machine monitoring enables maintenance teams to act before failures escalate, ensuring higher operational reliability and improved production stability.

Conclusion

Realtime machine monitoring is becoming a critical requirement for modern manufacturing. By combining IoT sensors, cloud platforms, and predictive analytics, companies can reduce unplanned downtime, optimize maintenance cycles, and significantly enhance operational performance. The continuous visibility provided by realtime machine monitoring transforms equipment maintenance from a reactive burden into a strategic advantage. As industrial environments evolve, realtime monitoring will continue to play a defining role in operational excellence and digital transformation.